Introduction

Guillaume Baron started Chicastprod with a straightforward goal: printing custom prizes for his Blood Bowl tournament. A friend from Crazy Mushroom suggested he buy a 3D printer and make the items himself instead of ordering them elsewhere. The players at his tournament loved the custom prints and kept asking where they could get more. That enthusiastic response turned what began as a simple tournament project into Chicastprod, a French 3D printing studio known for detailed miniatures that hold up to regular use.

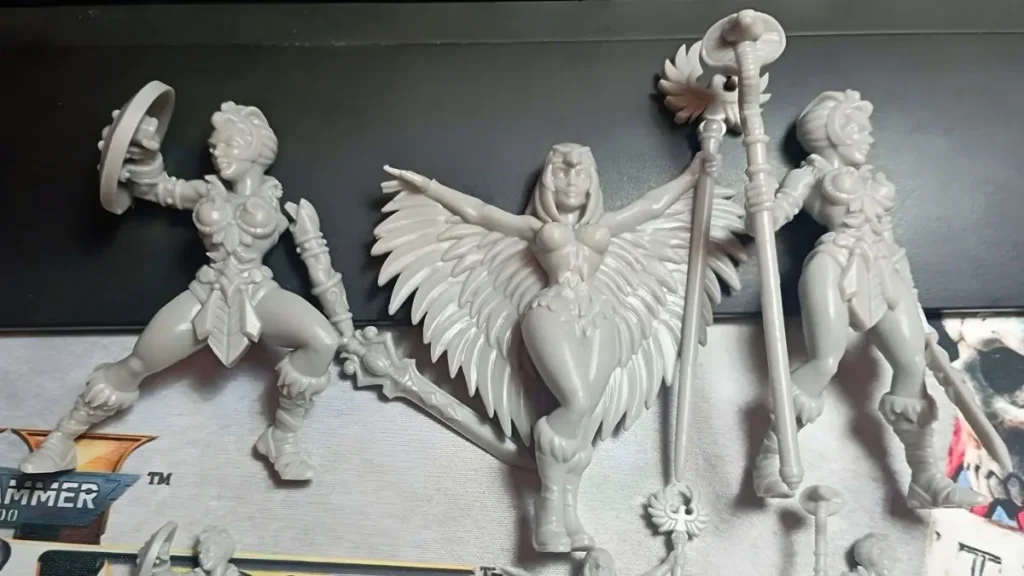

Today, Guillaume specializes in resin miniatures that need to deliver both fine surface detail and mechanical toughness. For professional printers running a business, this balance between aesthetics and strength matters significantly. Miniatures need to survive repeated handling during painting and gameplay, endure the stresses of packaging and shipping, and remain intact through regular tabletop use without breaking. After testing different resin formulations, Guillaume discovered that TGM-7 resin delivered both the surface quality his customers expected and the mechanical strength his business model required.

We asked Guillaume about his proudest prints, the biggest challenges he’s faced, and what he’s learned while building a miniature printing business.

The Interview

Out of all the miniatures you’ve printed, which one made you stop and say, “Wow, I actually made that?” Any wild stories behind it?

I’m proud of most of my prints. Lately, I’ve been printing large miniatures (between 20 and 25 cm tall) in PLA, and the results blew me away. The latest Machine models I bought still make me say “WOW” when I see the results. My tests with TGM-7 resin impressed me with the durability of the miniatures and the quality of the details.

What’s the trickiest miniature you’ve ever printed, and how did you solve it?

A 1:6 scale miniature of Daryl from The Walking Dead, lots of parts, sometimes too heavy for the build plate. A little waste and many, many hours of printing.

There are lots of resins out there. What made you pick AmeraLabs, and what difference has it made in your prints?

After receiving a sample, I was very impressed with the durability of the miniatures. Standard resin is very fragile, which sometimes bothers customers and increases breakage during shipping. Furthermore, the level of detail is much better with TGM-7 than with standard resins.

If another miniature printer asked for your top secret tips for flawless prints, what would you share?

The supports! You need good supports, adapted to the machine and its printing settings.

What future trends or techniques are you most excited about?

With multi-color FDM printers, prints are becoming cleaner and faster, but color management remains complicated. I’m convinced this will improve very soon.

From Hobby Project to Professional Studio

Guillaume’s journey from printing tournament prizes to running a professional studio demonstrates what happens when consistent quality meets genuine customer needs. His material choice reflects an understanding of what professional resin miniature printing requires: standard resin is fragile and sometimes bothers customers when breakage occurs during shipping. TGM-7 resin offers improved durability while maintaining the fine detail quality miniature painters expect.

For creators who are building miniature printing businesses rather than just printing as a hobby, material choice affects far more than the immediate print quality. The resin you select impacts long-term customer satisfaction, your return and replacement rates, and ultimately the reputation your business builds over time. Guillaume’s experience demonstrates how selecting the right resin formulation can make the difference between a hobby printer and a sustainable, professional business.

Follow Guillaume’s work on Instagram: @chicastprod

Learn more about TGM-7 resin: Product specifications and printing guide

Thanks for reading and see you in our next Client Spotlight, where we’ll keep sharing stories from the brilliant artists shaping the future of 3D printing.

Happy printing!