Brief overview of 2025 at AmeraLabs

2025 at AmeraLabs was all about meeting the community. We visited nine trade shows across Europe and North America, from wargaming conventions in Milwaukee and London to industrial 3D printing events in Birmingham and Frankfurt. We launched two products that pushed us further into new markets: FLX-300 elastomer resin for engineering applications, and GVA-26 gingiva resin for dental labs. Along the way, we wrote eight comprehensive guides, and kept supporting the miniature gaming community with resin prizes. Here’s how we spent the year proving that resin 3D printing goes far beyond tabletop miniatures.

Nine Trade Shows, Three Markets

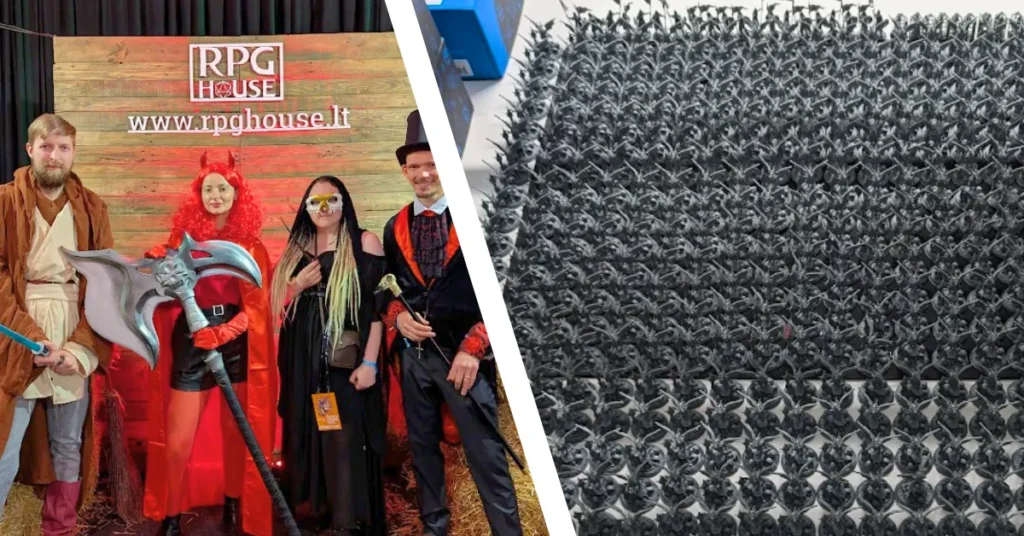

We spent 2025 meeting users where they gather. Nine trade shows across three distinct markets showed us how different communities use resin 3D printing and what they need next.

The Wargaming Circuit

Our co-founder Andrius attended Adepticon in Milwaukee (March 26-30). Meetings with STL creators, printer manufacturers, and resin users. The hobby in the US keeps growing, and so do the business opportunities around it.

Salute 52 in London (April 12) remains one of our favorite shows. We shared a stand with Neill’s Materials. They brought the printers, we brought the resin. This year’s Highlander theme brought out impressive display work across the hall. The tabletop hobby keeps growing year over year. Attendance and interest show no signs of slowing down.

UK Games Expo (May 30-June 1) let us try something different. Partnering with Deep Cut Studio for a Paint and Take event, we handed out printed miniatures from The Shattered Realms, including an exclusive piece for Trench Crusade. Watching people paint prints on-site showed us which details hold up under scrutiny and which wash techniques work best with our resins.

Tabletop Goes Mainstream

ComicCon Baltics in Vilnius (May 23-25) connected us with our home market. We brought over 400 dragon mascot miniatures for attendees to paint. Nothing tests a resin like handing prints to painters and watching what happens. Hearing the feedback in Lithuanian was a bonus.

Spiel Essen (October 23-26) reminded us how big tabletop gaming has become. Once again we had an epic collaboration booth with friends from De Tinnen Roos and Olmec Games. Walking halls of exhibitors, talking to designers about print quality requirements, and seeing miniatures made with our resins on demo tables across multiple booths confirmed the miniature market keeps expanding.

Professional Markets

IDS in Cologne (March 25-29) put us in front of dental professionals. Conversations centered on material accuracy, consistency across batches, and machinability for lab workflows. GVA-26 was our step deeper into this market. In 2026, we’re expanding: more dental expos starting with AEEDC Dubai, and a larger focus on dental 3D printing overall.

TCT 3Sixty in Birmingham (June 4-5) connected us with engineers and production managers. Questions focused on material consistency for batch production, heat resistance for functional parts, and cost per unit at scale. The kind of feedback that directly shapes what we develop.

PAMA Workshop in Boulder (September 15-16) brought our R&D team together with NIST and RadTech to work on photopolymer AM standards. The focus: standardizing how resin settings are measured and communicated across different printers and materials. Right now, every manufacturer uses different testing methods, making direct comparisons difficult. Unified standards would let dental labs and engineers compare resins on equal terms.

Formnext in Frankfurt (November 18-21) closed out the year. The show felt smaller this year. Attendance was down, some familiar brands were gone, others had merged or renamed. At the same time, one trend stood out: growing interest in resins for printing injection molding molds. Short-run manufacturing without tooling costs. We recorded a roundtable discussion with Lychee, Anycubic, and creators. Full recording coming soon.

Two Products, Two Problems Solved in 2025

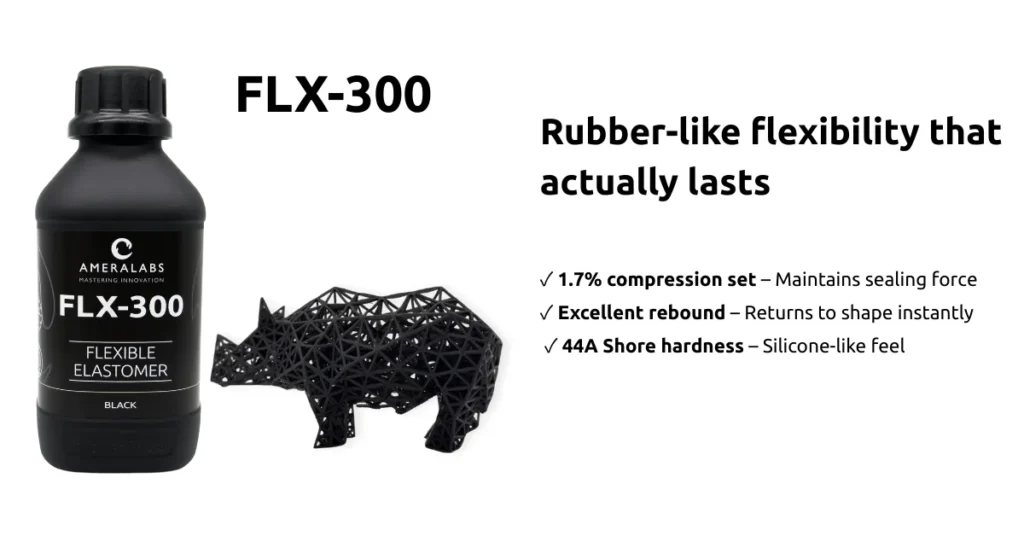

FLX-300: Flexible Resin That Stays Flexible

Flexible resins harden over time. You print a gasket, it works for a few weeks, then gradually turns rigid. We spent over a year solving this.

FLX-300 maintains its flexibility over time. Three months of testing in darkness and direct sunlight showed zero change.

We launched FLX-300 in October. Engineers use it for gaskets, seals, vibration dampers, and soft robotics. Full technical specs can be found here.

GVA-26: Gingiva Resin for Dental Labs

Dental labs needed gingiva material they could cut and drill without tearing. Try-in models require adjusting with scalpels and burs, and most flexible resins tear.

Development took slightly less than a year. GVA-26 handles standard dental tools without tearing, shrinks under 0.5%, and matches natural gingival tissue color.

GVA-26 launched in November. Dental labs use it for removable gingiva masks, soft-tissue models, and implant models. Technical data sheet here.

Community Recognition

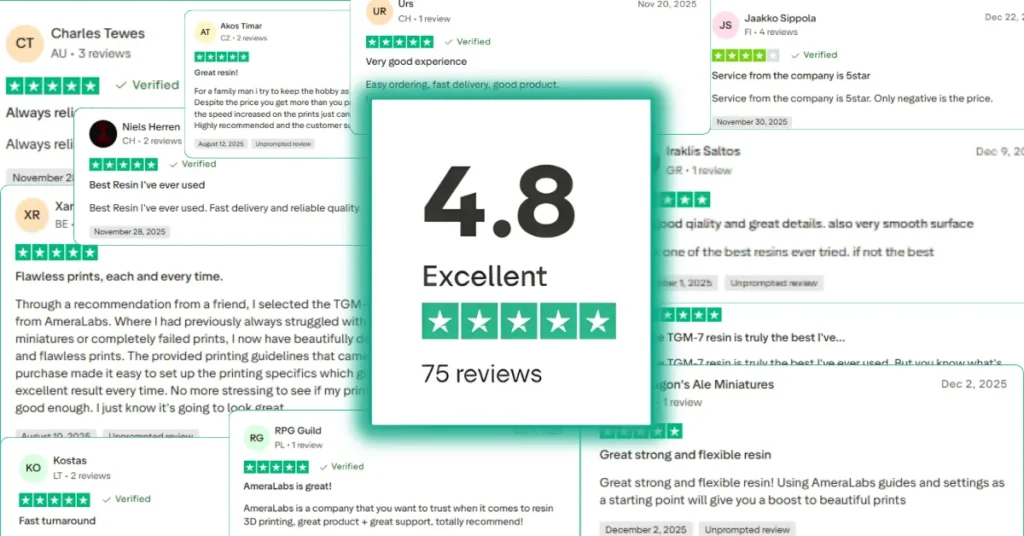

Supporting the miniature painting community stayed important to us this year. We sponsored Archvillain Games‘ year-long contest and kept partnerships going with Dragon Trappers Lodge and The Printing Goes Ever On, Lychee, donating resin as prizes. We made TGM-7 for miniatures that end up under a brush. Competition painters put that to the test better than any lab could.

We hit 4.8 on Trustpilot in 2025. The detailed reviews matter most: customers explaining their printer setups, their results, what worked and what didn’t. That’s how we learn what to improve. Tried our resins? Help us by leaving a review here.

Derek from Lychee reviewed our XVN-50 and TGM-7 resins in October. He tests dozens of resins and his honest assessments help makers choose what actually works for their needs. Watch it here.

The MTM Project partnership in July brought officially licensed Motörhead collectibles to resin printing. Metal music has a following at AmeraLabs, so this partnership mattered. MTM Project worked with Global Merchandising Services on the licensing, creating Lemmy Kilmister statues, War Pig pendants, and the iconic logo. First licensed rock merchandise designed for resin printing, opening a new category for the medium.

Building Knowledge in 2025 at AmeraLabs

Technical Research

April published the layer height research. We tested 10μm through 100μm on the same printer, using the same resin to eliminate variables. Microscope photography captured the differences between each setting, showing exactly where quality improvements plateau and where they matter. The finding: 50μm offers the best balance for most miniatures. Full guide includes methodology, microscope comparisons, and practical recommendations. Read the layer height research.

Business Guides

February’s Scaling Miniature Production walked through growing from hobby printing or small business to larger scale operations, covering everything from workflow optimization to managing resin waste.

March brought the Kickstarter guide. Four steps to running a successful campaign for miniature creators, from realistic goal-setting to backer management.

June released the STL Business guide. How to launch a digital miniature business in the $15.8 billion tabletop gaming market, from sculpting basics to platform selection.

Application Guides

February’s Warhammer guide tackled the legal landscape around 3D printing for Games Workshop’s IP. We covered what’s legal, what’s risky, and how to navigate the community’s most contentious copyright questions.

May covered Dungeon Masters. How to print custom TTRPG terrain, miniatures, and props that actually enhance gameplay instead of just filling shelf space.

Product Documentation

October’s FLX-300 printing guide followed the product launch, covering settings, troubleshooting, and application-specific recommendations.

December closed the year with the GVA-26 printing guide. Technical documentation for dental labs working with gingiva materials.

Browse all blog posts and guides here.

Research and Experiments

AmeraLabs hit nearly 1500 experiments in 2025. Theoretical knowledge points us in a direction, but experimentation determines if a formula actually works.

Each resin goes through rounds of testing for print & cure behavior, dimensional accuracy, mechanical properties, and real-world durability. Some formulas fail at step two. Others make it to step fifty before we find a problem. That’s how it works.

Looking Ahead to 2026 at AmeraLabs

2025 at AmeraLabs proved expansion works. Nine trade shows, two product launches, eight guides, and a 4.8 Trustpilot score showed us where to push next.

2026 brings more trade shows: AEEDC Dubai, Adepticon, Salute, UK Games Expo, Intermodelbau, GenCon, Spiel, Formnext, and possibly a few more. If you’re attending any of these, come say hello.

New products are in development. We’re also creating tools and educational content specifically for resin 3D printing businesses, not just individual makers.

Behind the scenes, we’re working on improvements to make finding information on our website easier. Better navigation, clearer product data, faster browsing.

And we’ll be printing. A lot. Subscribe to our newsletter or follow us on socials to stay updated.

Happy New Year and Happy Printing!