A Case Study

Introduction: Troubleshooting Curious Print Failures

In business resin printer maintenance, even minor issues can lead to significant setbacks.

This might sound like the beginning of a bad joke: a resin manufacturer, a 3D printer seller, a miniature maker, and a 3D printer manufacturer walk into a print room…

Let me share a story about four companies troubleshooting common print failures – visible horizontal layer lines and failed supports.

The involved companies were a miniature producer, a 3D printer manufacturer, a 3D printer reseller, and AmeraLabs, a resin producer. While I have great respect for these companies, I’ll refrain from naming the 3D printer manufacturer, the reseller, or the miniature producer. This was an unusual case, not a reflection of their product quality. Sometimes, coincidences happen, and this seemed to be a rare one-time occurrence.

Last month, a printer reseller asked us, “Have you changed your resin recently?” Upon investigation, we discovered that one of our customers – a miniature producer – was experiencing print issues. Their models were detaching from supports, and their high-end industrial DLP printers were showing visible horizontal lines on their miniatures. This was surprising, as we considered these printers to be consistent and reliable.

Chapter One: Identifying the Problem

The inquiry about the resin sparked our interest, leading us to conduct standard checks to ensure its quality and perform necessary business resin printer maintenance.

We double-checked the quality control documents of the resin batch the customer was using and re-ran tests. The resin’s reactivity and sedimentation were found to be normal. To determine whether the resin had changed properties, we compared the customer’s resin with an earlier batch.

We ran prints on our in-house printer equipped with force sensors using both resins, examining the height and force required to peel the test model off the FEP. Everything appeared normal, indicating that the resin itself was not the issue.

Meanwhile, our partner, the reseller of those printers, continued discussions with the customer, other users of those machines, and the producer of the 3D printers. After some time, one of the most apparent reasons emerged: the resin printer manufacturer had changed the film on their resin trays a few months ago, almost coinciding with the onset of print failures.

Chapter Two: Onsite Printer Maintenace

As the miniature producer faced mounting frustrations with their new high-end printers, we decided it was time for an onsite visit.

Together with the printer reseller, we flew to the customer’s location. The 3D printer manufacturer sent us new resin trays with prototype films installed. With only one and a half days to rectify the situation, we embarked on a comprehensive troubleshooting process.

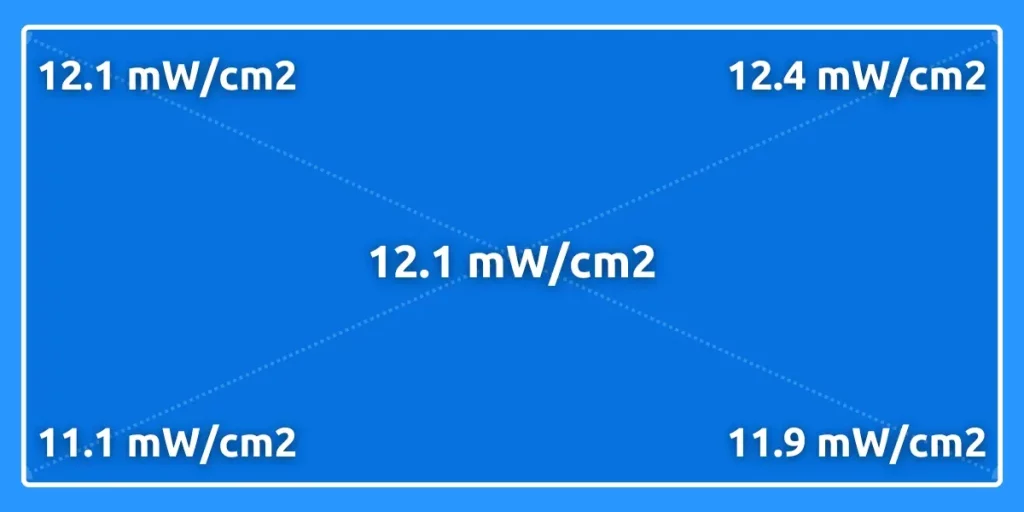

Our primary focus was business resin printer maintenance. We measured the intensity of the printer’s UV light using a spectroradiometer. Although the internal 3D printer’s radiometer required some calibration, the difference was insignificant.

We meticulously cleaned and leveled the build plate and thoroughly cleaned the glass screen. Upon inspection, we discovered white streaks caused by the customer’s glass cleaner. We advised them to switch to isopropanol and microfiber cloths, but we noticed cloudy streaks inside the screen. We disassembled it and cleaned it thoroughly.

Next, we checked the alignment of the DLP projector to ensure all light was perpendicular to the screen.

Following this, we 3D-printed parts and measured XY dimensions with a digital caliper, adjusting XY compensation for each printer. After recalibrating, we re-measured light intensity to ensure optimal performance. While calibrating one printer, we 3D-printed test models on the other using new resin trays and prototype films. The initial prints with the new trays showed significant improvement, indicating progress in resolving the issues.

Chapter Three: Unveiling the Culprit

During our troubleshooting process, we examined the failed models printed before our arrival. While some failures were due to inadequate supports or sudden changes in the models’ cross-sectional area size, most print lines and surface issues were exacerbated by problems with the resin trays.

In discussions with the customer’s team, we covered model orientation and support techniques, emphasizing the importance of consistent calibration procedures. Interestingly, we found that each team member had their own way of understanding and calibrating the printers, highlighting the need for uniform maintenance instructions and regular training.

I was particularly impressed by the team’s meticulous quality inspection and cleaning processes. They thoroughly analyzed each model under bright light, immediately identifying even the tiniest defects. Witnessing their attention to detail convinced me their products would be outstanding for their end customers.

Moreover, as we delved into the business resin printer maintenance process during our troubleshooting, our focus remained on achieving optimal printer performance.

Chapter Four: A Midnight Discovery

As our visit drew to a close, we decided to initiate a final print with more challenging models to ensure the printers’ flawless operation. After spending a few hours with the amazing team and enjoying some excellent food, we returned to the office around midnight to check the final print.

To our dismay, we discovered a strange gel-like residue on a couple of prints on one side of the build plate. Perplexed, we immediately contacted the 3D printer manufacturer to discuss this finding. Their instant response was, “That could be the contrast ratio of the DLP projector.” Further investigation confirmed that the “black” areas during printing were not fully “black,” leaking some light and slowly curing resin where it shouldn’t. We used a spectrometer to confirm that the contrast was indeed lower on the side that produced these issues.

The manufacturer suggested opening the printer’s side panel to check for dust, and sure enough, a significant layer of dust was found inside the printer. This dust had most likely also contaminated the projector, causing its contrast to drop. The only solution was to replace the printer’s entire DLP projector. Thankfully, the manufacturer agreed to send a new projector free of charge, and the reseller promised to return to replace it and recalibrate the printer.

To minimize future dust exposure, we advised the customer to thoroughly clean the 3D printing room and printers and ensure proper filtering on the air venting system. We also recommended minimizing the use of paper towels and switching to lint-free wipes.

Business Resin Printer Maintenance: Conclusion

In conclusion, the successful resolution of this case study underscores the importance of thorough business resin printer maintenance and proactive troubleshooting.

Through this process, we’ve learned valuable lessons that will shape our approach to similar challenges in the future. Collaborative efforts were key to achieving a solution. From the printer reseller to the 3D printer manufacturer and the dedicated team at AmeraLabs, everyone contributed to identifying and addressing the root causes of the print failures.

Moving forward, we are committed to continuously improving our maintenance procedures and troubleshooting techniques. By sharing our experiences and insights, we aim to help our clients maximize the performance and reliability of their 3D printing operations.

We sincerely thank the miniature producer for their patience and cooperation throughout this process. Challenges like these strengthen our partnerships and reaffirm our commitment to delivering exceptional products and support.

As technology evolves, we remain dedicated to staying at the forefront of innovation in the 3D printing industry. With a proactive approach to maintenance and problem-solving, we’re confident that we can overcome any challenge that comes our way.

This case study is a testament to the power of collaboration, innovation, and perseverance. By working together and leveraging our collective expertise, we can overcome even the most curious of print failures and ensure the continued success of our client’s manufacturing operations.

TL;DR: Business Resin Printer Maintenance

A series of 3D printing failures threatened production for a high-profile client. Through meticulous investigation, focusing on business resin printer maintenance, and collaborative problem-solving, we identified and addressed the root cause of these issues. This ensured our client’s manufacturing operations continued smoothly.