Comparative Analysis of FEP, nFEP, and ACF Films for 3D Printing

ACF, FEP, and nFEP are well-known materials used for 3D printer vats and trays. Traditionally, FEP film has been the go-to option, but nFEP has since emerged as a promising alternative, offering quicker print speeds and a longer film lifespan. Recently, ACF film has entered the market, boasting “almost no release force,” an extended service life, and a respectable light transmittance of 93%. But does the claimed increase in print speed justify the higher cost? And could a 300 µm thick matte film compromise print detail? Let’s explore the performance of ACF compared to nFEP and FEP films.

How did we test the chosen FEP, ACF & nFEP films?

To evaluate these films, we tested five variants: FEP sheets with thicknesses of 50, 127, or 150 µm; a 127 µm nFEP sheet; and a 300 µm ACF sheet.

We assessed various factors, including light intensity, peel force, layer surface area, print speed, and print detail quality. Light intensity was measured using an Ocean Optics ST-UV-25 spectrometer with a Mars 4 DLP printer as the light source. All measurements were recorded at the same position on the printer’s tempered glass, with different films placed between the spectrometer probe and the glass.

For printing tests, we used an Asiga Max X43 DLP printer with AmeraLabs TGM-7 Grey resin. Each vat was filled with 40 g of resin. We printed AmeraLabs town models at a 50 µm layer height, using an exposure time of 0.276 seconds and a light intensity of 25 mW cm². All settings remained consistent across different films. Lift height and separation detection data were collected from the printer’s log files. The lab conditions were maintained at 23±1°C and 40±10% relative humidity.

After printing, the AmeraLabs towns were washed in isopropanol for 10 minutes, dried for 15 minutes, and post-cured for 5 minutes.

Light intensity measurements of ACF, FEP & nFEP films

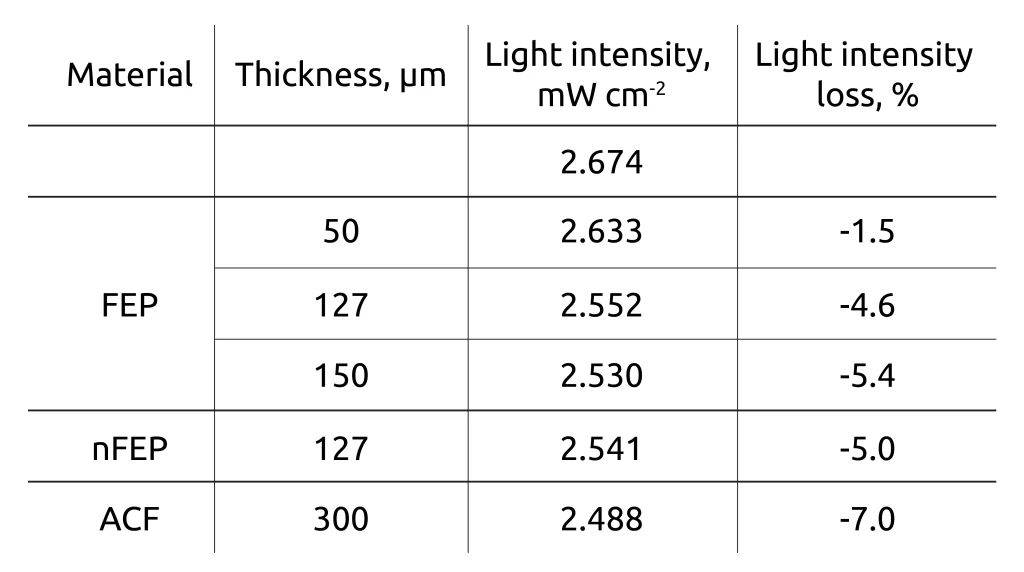

To determine exposure adjustments needed for different UV light absorption, we tested all films with the Mars 4 DLP printer. The results are shown in the table below.

Increasing the thickness of FEP films led to higher light absorption, ranging from -1.5% to -5.4%. This change is minor and likely not noticeable in exposure settings. nFEP films absorbed slightly more light than equivalent thickness FEP films. ACF, with its 300 µm thickness, absorbed 7% of the light, which aligns with the manufacturer’s data.

To provide a perspective, if you were printing with 50 um FEP sheet at 2 s exposure and decided to switch to ACF, you would have to increase your exposure to 2.12 s. This small change could be noticeable in some cases, so if you had your exposure dialed in, you might need to increase your exposure slightly when switching to ACF.

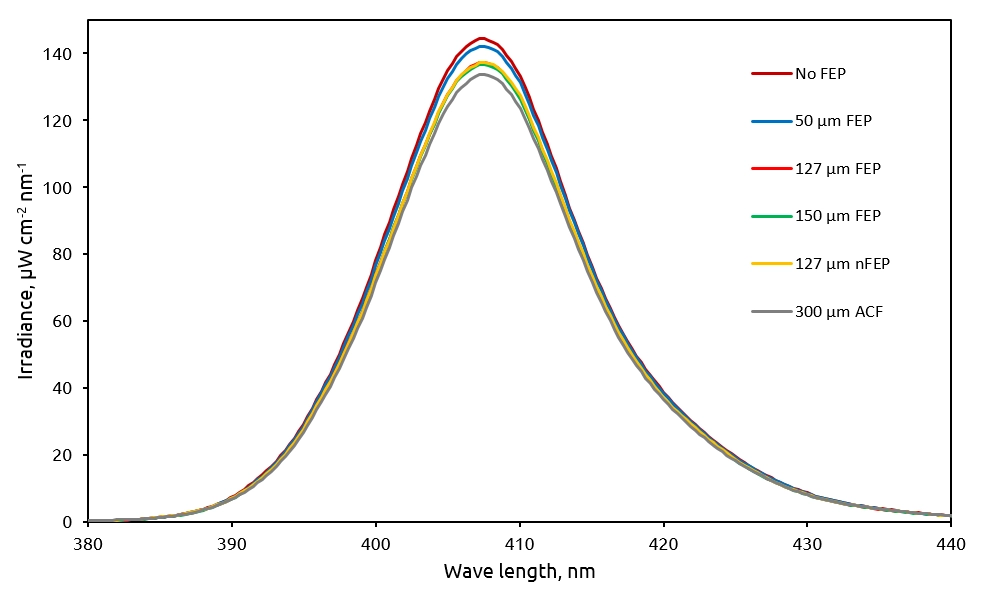

We also recorded the UV spectrum of the light that has passed through the different 3D printing films.

Here you can see a uniform reduction of irradiance throughout the emission spectrum of the printer. The curves of 127 µm FEP, 150 µm FEP, and 127 µm nFEP are indistinguishable from each other and overlap almost completely. That means that all films block light at different wavelengths similarly and there is no significant blocking of light with a specific wavelength. What is unrelated to this blog post but is very interesting is that the emission spectrum peak is 407.5 nm, even though the printer is advertised as 405 nm.

Comparing FEP, ACF & nFEP peel force vs. layer surface area

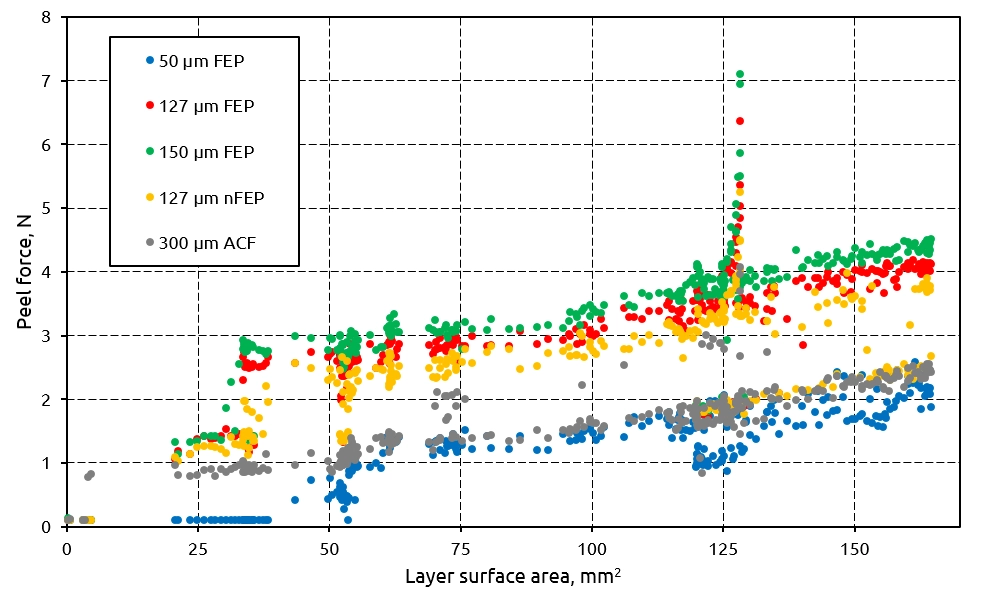

Asiga Max printers are equipped with load cells that detect print release by measuring sudden changes in load. This data allows the printer to halt the Z-axis movement immediately upon detecting separation, which optimizes printing time. The printer’s log files record the maximum weight and the Z-axis travel distance before separation for each layer, providing valuable data for comparing different 3D printing films.

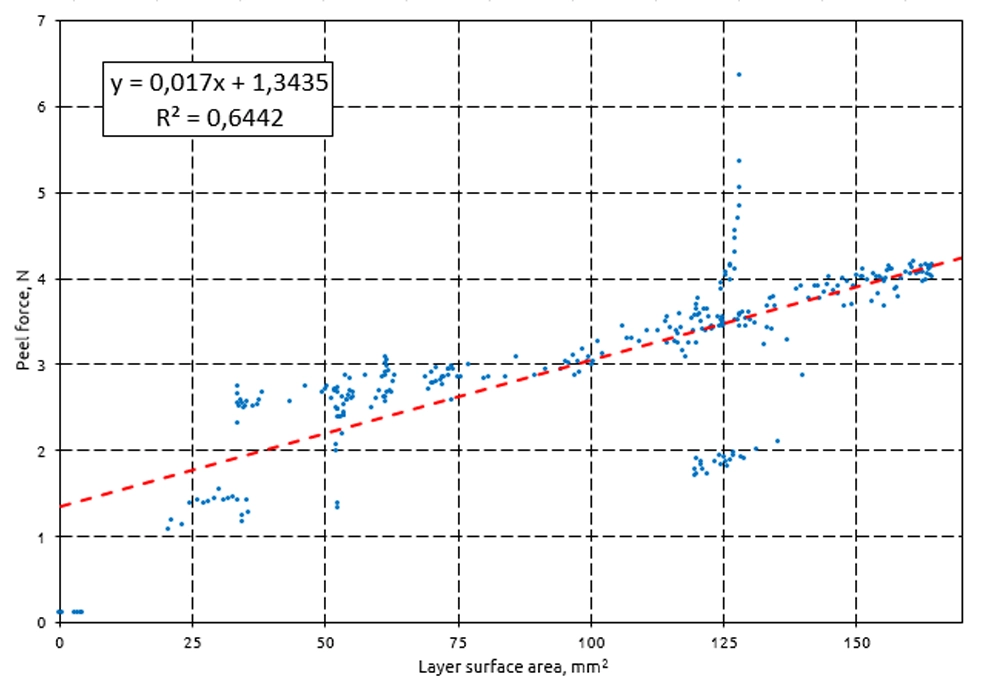

Peel Force vs. Layer Surface Area

The chart below illustrates how peel force varies with layer surface area. As expected, peel force increases with larger surface area layers. A notable spike in peel force occurs around 125 mm². This spike is likely due to the build plate being submerged in resin and close to the tempered glass, affecting separation. We found that thicker FEP sheets generally lead to higher peel force. Although there is a slight decrease in peel force when comparing FEP to nFEP, 50 µm FEP exhibited the lowest peel force among all tested films, with ACF film showing a similar but slightly higher value.

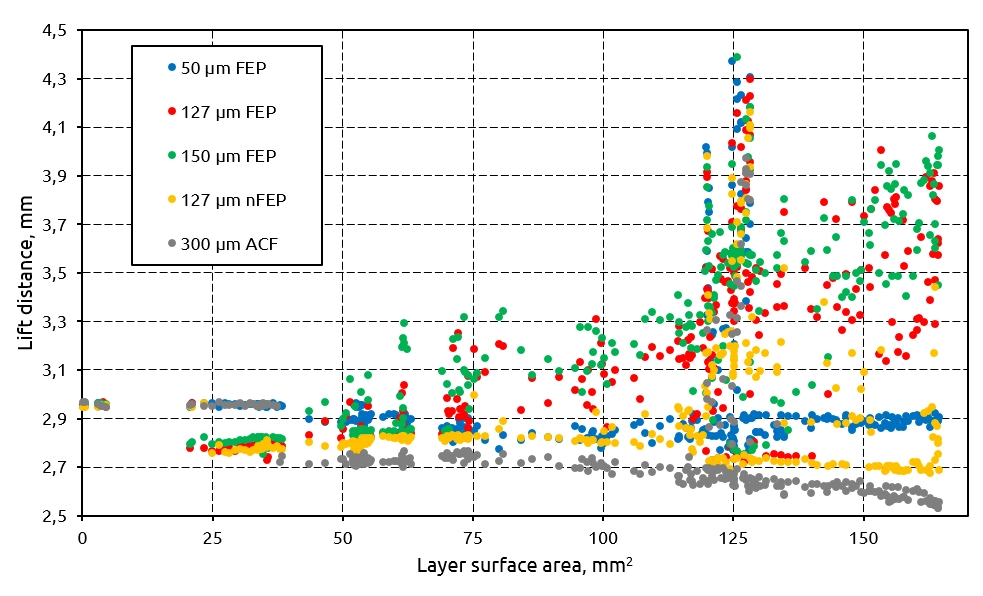

Lift Distance vs. Layer Surface Area

The correlation between lift distance and layer surface area was less straightforward. While lift distance increased with 127 µm and 150 µm FEP films, other films displayed more consistent lift heights or even a decrease, particularly with ACF and nFEP. This variability may stem from the Asiga printer’s method of lifting the build plate and detecting separation rather than differences between the films. Overall, ACF had the lowest lift distance, followed by nFEP and 50 µm FEP. The chart below compares lift distance against layer surface area for different 3D printing films.

Which films resulted in the fastest printing?

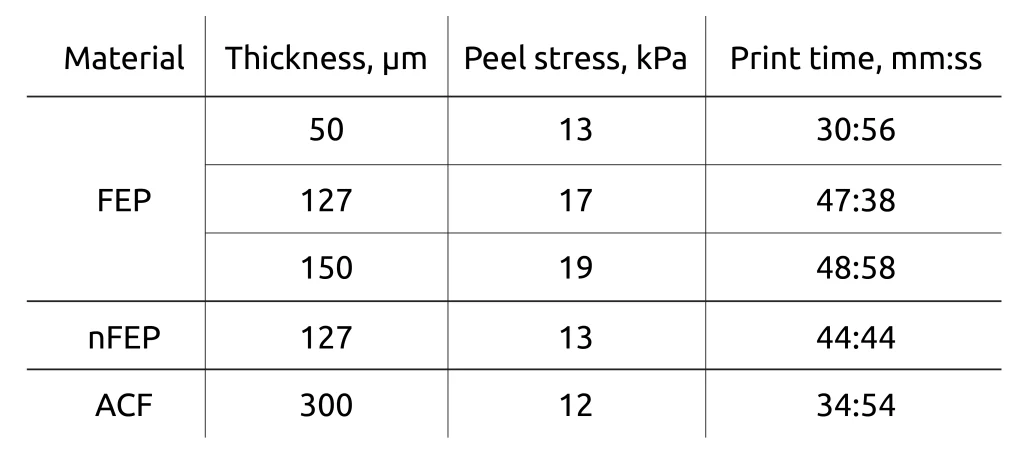

We determined print times by reviewing the printer logs. The fastest print was achieved with 50 µm FEP film, taking 30 minutes and 56 seconds. This speed could be due to the Asiga printer’s Separation Pressure limit feature, which allows faster build plate lifting with lower peel forces. However, this feature is not present in all printers, so 50 µm FEP might perform differently on other models.

The second fastest print was with ACF film, as expected from manufacturer claims. nFEP was about 10 minutes slower than ACF, while thick FEP films resulted in the slowest print times.

We also calculated the impact of peel force on the layer surface area using a linear fit to the data. The coefficient, known as peel stress, was measured in pascals (Pa). ACF had the lowest peel stress at 12 kPa, followed by 50 µm FEP and 127 µm nFEP, with 127 µm and 150 µm FEP showing the highest peel stresses. This suggests ACF is advantageous for printing large models with extensive surface areas due to its slower increase in peel force.

You can see the peel stresses for each film in the table below. The larger number, the larger increase in peel force. ACF had the lowest value of 12 kPa, then a small jump to 13 with 50 µm FEP and 127 µm nFEP, and the worst performers were 127 and 150 µm FEP. That means that with increasing surface area, the peel forces do not increase very fast on ACF film. In contrast, the peel force changes more quickly for the thickest FEP film. This also shows, that ACF might be a good choice if you are printing big solid models with very large layer surface areas.

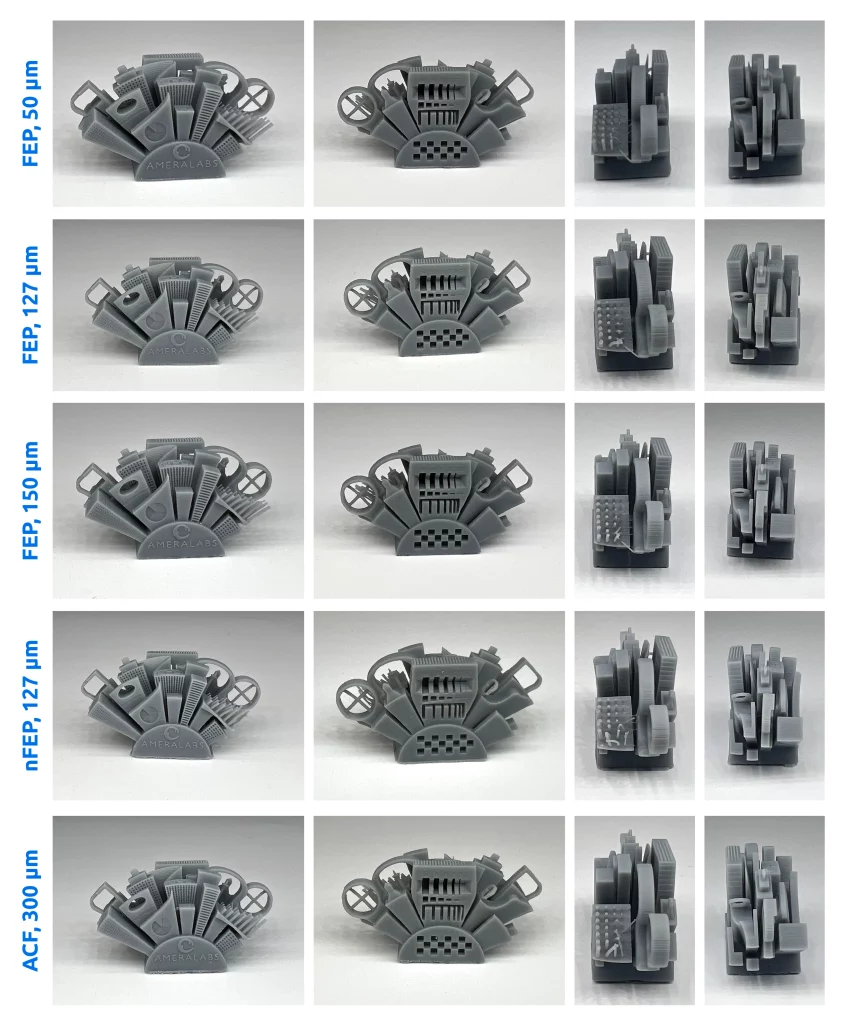

Which 3D printing film produced the best details?

We visually assessed print quality by examining photos of AmeraLabs towns printed with various films. All films produced similar results, with the checkered pattern indicating good exposure consistency. However, ACF prints exhibited more vertical lines on flat surfaces, suggesting that ACF might introduce more texture. Additional tests confirmed this trend.

So is ACF an alternative worth considering?

Overall, ACF film fulfills its promises of faster printing speeds, lower peel force, and not that much greater UV light absorption while still retaining details on the printed parts. This should be especially beneficial when printing with printers that have bigger screen sizes and prints that have larger surface areas. However, the presence of visible vertical lines and the significant price increase could deter you from switching to it. Especially since 50 µm FEP performed very well in this short test which could be a good option for small printers and people who do not mind changing the film more often. The only thing that is very important and we haven’t tested yet is the durability of the films. Hopefully, we will crowdsource from the feedback of the community. So if you have tried different 3D printing film materials, feel free to provide your insight.

Related Posts:

- Key Things to Know Before Calibrating Resin 3D Printer – Changed FEP to ACF? Got a new resin? This helps you calibrate.

- Resin 3D Printing Troubleshooting: A Comprehensive Guide – Changing FEP did not help? This fixes it.

- TGM-7 Resin Printing Guide – Changed FEP, bought TGM-7 and ready to print? This shows you how.

- Misbehaving 3D Printers – Sometimes you need more than a FEP change. This digs in.

- 9 Settings to Change for Faster Resin 3D Printing – Speed up your prints. ACF might come in handy!

Picking films? Swing by our shop for resins that’ll work with whatever you choose!