Introduction

In the rapidly evolving world of 3D printing, selecting the optimal resin is essential for achieving high-quality prints. Among the wide range of options, XVN-50 resin is distinguished by its superior durability, flexibility, and precision. This versatile engineering resin is meticulously designed to cater to the demands of both functional and aesthetic applications, making it an ideal choice for professionals in various industries. Whether you’re working on intricate prototypes or robust functional parts, XVN-50 resin offers the performance and reliability needed to excel in any project.

Summary of Essential Tips for XVN-50 Resin 3D Printing:

- Mix the Resin: Vigorously shake the bottle to evenly distribute pigments before pouring into the vat.

- Begin with the initial recommended settings and set the bottom layer exposure to 10X the regular layer exposure.

- Set layer height between 0.05-0.1mm for fine details.

- Adjust lift speed and retract speed for better adhesion and reduced suction forces.

- Printer Setup:

- Level the build plate.

- Begin with recommended exposure settings.

- Keep the resin at a stable temperature (20-25°C).

- Print AmeraLabs Town to fine-tune the exposure.

- Print Settings:

- Hollow objects and add drainage holes to save resin and prevent trapped resin.

- Ensure proper support structures (use 1.5-2 mm column thickness, 0.2-0.5 mm tip thickness).

- Post-Processing:

- Wash prints in IPA for 10 minutes and dry for 30 minutes.

- Post-cure for 15-60 minutes under 395-405nm UV light.

- Finish:

- Remove supports before post-curing for smoother results.

- Sand, drill, or coat as needed.

- Troubleshoot common issues like adhesion, warping, or incomplete curing by adjusting exposure settings or support density.

- If prints fail, adjust exposure times or increase support density.

- Avoid over-curing to prevent brittleness.

Why XVN-50 Resin?

XVN-50 versatile engineering resin is specifically designed to excel in environments where traditional resins might fall short. For instance, its high impact resistance makes it ideal for parts subjected to rigorous conditions, while its precision ensures that even the most intricate designs are accurately realized. Whether you are prototyping new products, creating detailed models, or producing end-use parts, XVN-50 resin consistently provides the reliability and performance needed to achieve superior results.

Key Advantages of XVN-50 Resin

Durability: To begin with, XVN-50’s robust mechanical properties, including high tensile strength and impact resistance, make it particularly suitable for parts that must endure physical stress and wear. Moreover, this durability is invaluable in engineering applications where parts need to maintain their integrity under demanding conditions.

Precision: In addition to its durability, the resin’s ability to produce dimensionally accurate prints ensures that prototypes and final products meet exact specifications. This precision is especially crucial for rapid prototyping, where meticulous detail and consistency are key to refining and perfecting designs.

Flexibility: Furthermore, with its notable flexibility, XVN-50 resin can be used for parts that require slight deformations without breaking. This makes it an excellent choice for mechanical joints, flexible connectors, and other applications where some degree of flexibility is necessary.

How This Guide Will Help You

This comprehensive guide is designed to help you fully utilize XVN-50 resin. First, we will walk you through the essential steps of preparing your printer, optimizing print settings, and mastering post-processing techniques. Additionally, you will find troubleshooting tips for common issues and special considerations to ensure that your prints come out perfect every time.

By following the insights and recommendations provided, you will not only be equipped to tackle various 3D printing projects with confidence but also enhance your overall printing experience. Whether you’re an experienced professional or just starting out, understanding how to leverage XVN-50 resin’s unique properties will significantly elevate your 3D printing capabilities and ensure greater success in your projects.

The Importance of Thoroughly Mixing XVN-50 Resin for Optimal 3D Print Quality

Thoroughly mixing the XVN-50 resin before adding it to the vat is crucial for successful 3D printing. This resin contains black pigments that tend to settle at the bottom of the container due to natural separation. If these pigments are not evenly redistributed before use, several issues can arise, compromising print quality.

For example, inadequate mixing can lead to uneven color distribution, resulting in prints with blotchy or inconsistent hues. Additionally, settled pigments can cause print failures, such as weak adhesion to the build plate, which may lead to prints shifting or detaching mid-process. The surface of the print might also become uneven, with areas of slight to moderate transparency where the resin wasn’t properly mixed.

To avoid these problems, it’s essential to vigorously shake the resin bottle before pouring it into the vat. This ensures the pigments and other additives are thoroughly dispersed, maintaining a homogenous mixture that supports consistent curing and reliable print results. Properly mixed resin not only improves the aesthetic quality of your prints but also helps maintain the mechanical integrity and adhesion necessary for complex or delicate models.

By making this a regular part of your 3D printing routine, you can maximize the performance of the XVN-50 resin and avoid common issues related to pigment settling. For more insights, check out our blog post, “Why Mixing Resin Bottles is So Important?“

Hollowing Objects and Drainage Holes

Hollowing objects and adding drainage holes are key techniques in XVN-50 resin printing, though they’re not always necessary. Solid prints are often preferable for parts requiring high dimensional accuracy or structural integrity. However, hollowing can conserve resin, reduce print failures, and decrease curing times when appropriate.

To hollow effectively, first identify non-structural areas that can be emptied without compromising functionality. While automated hollowing tools in your slicing software are useful, manual refinement may still be needed. Aim for a wall thickness of 2-3mm, adjusting as needed for larger or more delicate prints.

Furthermore, drainage holes are crucial for hollowed models. They allow uncured resin to escape during printing and ensure thorough cleaning. Without proper drainage, trapped resin can lead to incomplete curing, increased weight, and potential cracking. Place holes strategically, considering both functionality and aesthetics, with optimal locations being the bottom or less visible areas.

Include at least two holes: one for resin escape and another for airflow. Typically, hole diameters range from 3 to 5mm, depending on the model’s size and resin viscosity. For complex or larger prints, you may need additional or larger holes.

Finally, because XVN-50 resin features high dimensional accuracy and rapid curing, proper hollowing and drainage are even more critical. Its properties allow for thin, sturdy walls suitable for intricate designs, but quick curing means trapped resin can quickly become problematic if not addressed properly.

Support Strategies for XVN-50 Resin

Effective support structures are essential for achieving successful prints with XVN-50 resin. Here’s a focused guide to optimizing your support configurations:

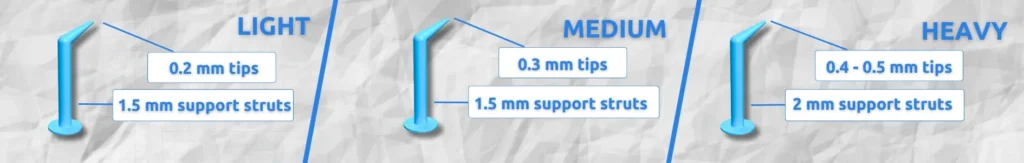

1. Support Column and Tip Thickness:

- Support Column Thickness: Use a thickness of 1.5-2 mm for support columns. This size provides strong support to keep the model stable while still being easy to remove.

- Support Tip Thickness: Opt for a tip thickness of 0.2-0.5 mm. Prioritize 0.3 mm support tips, and use 0.2mm tips for delicate parts where support marks are detrimental. This ensures that supports are robust enough to hold the model securely without leaving excessive marks on the surface.

2. Attachment Layer:

- Utilize an Attachment Layer: Incorporate an attachment layer to enhance support stability. This additional layer helps to adhere the supports to the build plate better, reducing the risk of detachment during printing.

3. Support Density and Placement:

- Density Adjustments: Tailor the density of supports based on the complexity and size of your model. Higher-density supports are generally needed for larger or more intricate prints to ensure adequate stability.

- Strategic Placement: Place supports in areas with significant overhangs or complex geometries to prevent issues such as sagging or detachment. Proper placement helps to maintain the model’s integrity throughout the printing process.

4. Orientation and Efficiency:

Model Orientation: First, orient your model to minimize the number of required supports. Proper orientation not only reduces the use of support material but also simplifies post-processing, ultimately leading to higher-quality prints. Avoid placing supports in critical places of the model, tilt the model to avoid large cross-sectional areas or overhangs,

Adhering to these support strategies can help you optimize your XVN-50 resin prints and achieve better results. For further assistance or troubleshooting, please do not hesitate to contact us at support@ameralabs.com.

Exposure Times and Optimal Temperature for XVN-50 Resin

Achieving the best results with XVN-50 resin involves careful attention to exposure times and temperature control. Here’s how to optimize these settings for high-quality prints:

1. Exposure times for XVN-50 resin – Town Calibration Part:

Bottom Layer Exposure: Begin by using the initial bottom layer exposure settings recommended for your specific printer, which can be found on our Initial Exposure Settings page. Print the AmeraLabs Town calibration part to help determine the optimal exposure settings for your setup. This will ensure strong adhesion of the first layer to the build plate and help avoid issues such as separation from the FEP film or PDMS silicon.

Standard Layer Exposure: Next, use the Town calibration part to determine the standard exposure time for subsequent layers, which can vary depending on your printer. Begin with the initial settings, then adjust as needed to find a balance between accurate curing and efficient printing. Consequently, this approach will ensure detailed and reliable results.

Test and Fine-Tune: After printing the Town calibration part, inspect it using the guidance provided in our calibration guide. Based on your observations, adjust the exposure settings as necessary to meet the specific requirements of your models and environmental conditions.

For more detailed instructions, please refer to our updated blog post on the AmeraLabs Town Calibration Part & Guide. In this post, we explore its features and tests in depth, offering a comprehensive toolkit for achieving exceptional print quality and precision.

2. XVN-50 Resin Temperature Control Tips:

- Resin Temperature: To ensure optimal results, keep your XVN-50 resin at a stable temperature between 20-25°C (68-77°F). Fluctuations in temperature can adversely affect the resin’s viscosity and curing efficiency. Thus, maintaining a consistent temperature is essential for preserving print quality and consistency.

- Printer Environment: Additionally, operate your 3D printer in a light and temperature-controlled environment to avoid direct sunlight or light sources that match the curing wavelength of XVN-50 resin. Consequently, a stable environment is crucial for achieving consistent curing and maintaining high print quality.

- Pre-Warming Resin: If your resin has been stored in cooler conditions, warm it gently to the optimal temperature before use. To avoid altering the resin’s properties, ensure it does not exceed the maximum recommended range (40°C —50 °C). A simple way to do this is to place the resin bottle in a container with warm water.

Optimizing Raft Settings for XVN-50 Resin

The raft, or attachment layer, is vital for ensuring strong adhesion between the build plate and your 3D print’s first layer. Here’s how to optimize your raft settings with XVN-50 resin for the best results:

1. Recommended Raft Thickness for XVN-50 resin:

For effective adhesion and easy removal, set your raft thickness according to your layer resolution:

- 50 µm Layer Resolution: 0.05 mm to 0.2 mm.

- 100 µm Layer Resolution: 0.1 mm to 0.2 mm.

Ensure you have 2-4 layer raft thickness. This thickness range balances support and adhesion without complicating the removal process.

2. Addressing Common Raft Issues:

- Layer Delamination: Excessive raft thickness can lead to stress during separation, increasing the risk of delamination. Maintaining the recommended thickness minimizes this risk.

- FEP Wear: Thick rafts place additional stress on the FEP film, potentially leading to wear faster and reducing the lifespan of your printer’s components.

- Removal Challenges: Although thicker rafts are often easier to remove, they can cause increased wear on the FEP film and separation between raft layers.

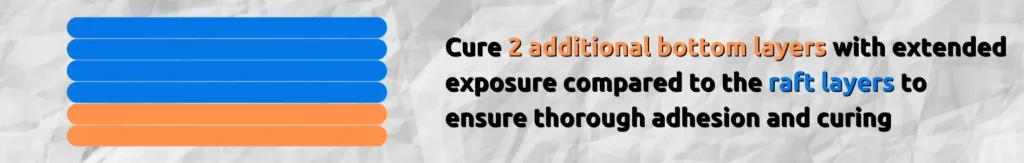

3. Additional Tips:

- Increased Exposure: Cure 2 additional bottom layers with extended exposure compared to the raft layers to ensure thorough adhesion and curing.

For more detailed insights into raft optimization, read our article, Why You Should Not Use Default 3D Printing Raft Settings. By following these guidelines, you can enhance print reliability and achieve high-quality results with XVN-50 resin.

Cleaning XVN-50 Resin Prints

First things first: We highly recommend washing, drying, and post-curing as soon as the print has finished printing to prevent warping and other issues. XVN-50 prints have a softer, more prone-to-scratching surface before the print is post-cured. When multiple parts are washed all at once in a single wash and cure station, they tend to rub against each other and damage the surface. If you plan on priming or painting the finished part, you can wash the parts together, as primer and paint will give a nice surface finish. On the other hand, if you want a smooth, scratch-free surface without priming or painting, please handle XVN-50 prints with care until they are completely post-cured.

Avoid Extended Submersion:

Do not leave your prints submerged in solvents like IPA (Isopropyl Alcohol) for more than 1 hour. Extended contact can degrade the models and affect the final properties of the resin.

Using an Ultrasonic Cleaner:

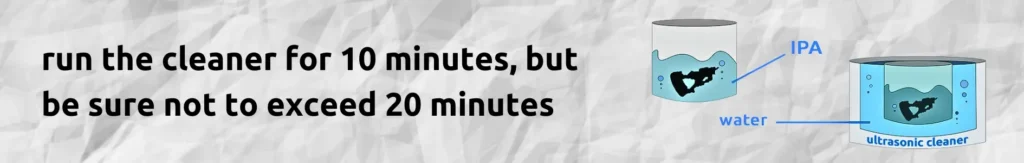

To start, if you are using an ultrasonic cleaner, place the printed part in isopropyl alcohol (IPA) within the cleaner’s container. Next, seal the container and then submerge it in water inside the ultrasonic cleaner. Subsequently, run the cleaner for 10 minutes, but be sure not to exceed 20 minutes. Additionally, no extra heating is needed during this process.

Using a Wash and Cure Station:

If you have a Wash and Cure station, submerge the printed object in IPA for 10 minutes. Depending on the results, you may repeat the wash for an additional 10 minutes. This method effectively cleans while maintaining the quality of your prints. Note that when multiple parts are washed together, they may rub against each other and potentially damage the surface. Consider washing parts individually for optimal results if you desire a scratch-free surface.

Cleaning XVN-50 Resin Prints with Ordinary IPA Baths:

For a manual cleaning approach, follow these four steps:

- Step 1: After removing the printed object from the build plate, submerge it in an IPA bath for 10 minutes.

- Step 2: Swirl the IPA bath actively for 1 minute to ensure thorough exposure to the solvent.

- Step 3: Allow the object to remain fully submerged in IPA for another 10 minutes. If it becomes too contaminated, consider changing the IPA.

- Step 4: Swirl the bath again for 1 minute and evaluate the cleaning results. If necessary, repeat this procedure only once more.

Some prefer to remove supports before washing to reduce IPA contamination, while others find it easier to remove supports after washing despite potential IPA contamination. Removing supports after post-curing is not recommended, as they become hard and can leave dents on the supported surface. If the supports are hard to remove, try submerging the printed part in warm water for a short period of time to soften them. Keep in mind that prolonged contact with water might cause warping, bloating, and other issues.

Drying and Post-Curing Process for XVN-50 Resin

Proper drying and post-curing are essential steps in achieving durable and high-quality prints with XVN-50 resin. Follow these detailed instructions and tips to ensure your prints meet the desired standards.

Drying the XVN-50 Prints:

- Initial Drying: After washing your printed objects, allow them to dry for at least 30 minutes. This step removes excess solvent and prepares the prints for post-curing.

- Accelerate Drying: To speed up the drying process, use a cold fan or compressed air. This helps remove residual liquid and minimizes the risk of residue affecting the final finish.

Post-Curing Instructions for XVN-50 resin:

- Remove Supports: For optimal results, remove supports before post-curing. This approach can reduce the likelihood of support marks on your prints. However, you can also post-cure prints with supports still attached and remove them afterward if this method suits your specific needs.

- Post-Curing Time: The post-curing duration will vary depending on your curing station. Generally, this process takes 15 minutes to 1 hour ( we post-cure with 50W of 395-405nm LEDs for 1 hour for the best results). Ensure that the surface of your 3D print becomes non-sticky and fully cured. The print should be placed in the curing station immediately after drying to achieve the best results.

Post-Processing: Drilling, Tapping, Threading, Sanding, and Coating

Effective post-processing is key to achieving professional results with XVN-50 resin prints. Here’s a brief guide to enhancing durability and appearance through drilling, tapping, threading, sanding, and coating:

Drilling, Tapping, and Threading: Use sharp high-speed steel (HSS) drill bits, starting with a small size and gradually increasing to avoid cracking. Drill at slow to moderate speeds with steady pressure to prevent overheating and ensure clean holes. When tapping, use plastic or resin-specific taps with a tapered lead to minimize cracking. Turn slowly and back out periodically to clear debris. Apply light pressure when using dies for external threads or taps for internal ones to avoid damaging the resin.

Sanding: Start with coarse sandpaper (120-220 grit) and gradually move to finer grits (400-600 grit). For intricate areas, use sanding sponges or rotary tools. Sand in circular motions to maintain an even surface. Wear a mask to avoid inhaling particles, and tape off areas you want to protect.

Finishing: After sanding, clean off dust using compressed air or a brush. Buff to a smooth finish with resin polish or a fine compound. Apply spray paints or coatings for your desired look.

Coating: Apply a clear resin or acrylic spray for protection against moisture, UV light, and chemicals. For a glossy finish, use resin or spray lacquer, applying thin, even layers and allowing ample drying time between coats.

These steps will enhance the quality and durability of your XVN-50 resin prints.

Troubleshooting Common Issues

XVN-50 resin is a high-quality material designed for reliable 3D printing, but like any resin, you might encounter occasional issues such as adhesion problems, warping, or failed prints. Here’s how to effectively troubleshoot and prevent these common challenges:

1. Adhesion Issues:

- Problem: Prints are not sticking to the build plate.

- Solution: Ensure the build plate is leveled and clean. Clean the build plate and resin vat with isopropyl alcohol (IPA). Increase bottom layer exposure, use rafts/supports to improve adhesion, and if all else fails, try sanding the build plate.

2. Warping:

- Problem: Prints showing warping or deformation.

- Solution: Warping often results from improper temperature or insufficient support. Keep the resin at a stable temperature (20°C-25°C or 68°F-77°F). Adjust the build plate height for proper bottom layer adhesion, increase support density, and optimize model orientation.

3. Failed Prints:

- Problem: Incomplete or partially cured prints.

- Solution: Check exposure settings for the XVN-50 resin; underexposure can cause incomplete curing. Ensure the resin is well-mixed and there are no clogs in the vat. If prints fail in specific areas, inspect the printer’s UV light source and build plate alignment.

4. Surface Imperfections:

- Problem: Rough or uneven surfaces.

- Solution: Improve support placement and increase density to reduce imperfections. Post-process with sanding and coating for a smooth finish.

5. Preventive Measures:

- Regular Maintenance: Regularly clean and inspect your printer and resin vat to prevent issues from debris or residue build-up.

- Calibration: Frequently calibrate your printer to maintain accurate settings and alignment.

- Test Prints: Use small test prints to fine-tune settings before larger projects.

By implementing these strategies, you can address and prevent common issues, thereby enhancing the reliability and quality of your XVN-50 resin prints.

For additional guidance, solving other issues, and detailed troubleshooting tips, please refer to our comprehensive guide, “Resin 3D Printing Troubleshooting.“

Summary and Key Takeaways

In summary, working with XVN-50 resin not only offers exceptional durability but also delivers precision for your 3D printing projects. To achieve the best results, optimizing support structures, adhering to recommended exposure times, and carefully monitoring temperature settings is crucial. Additionally, applying thorough post-processing techniques is essential for refining your prints. Furthermore, regularly calibrating your printer, monitoring resin temperature, and maintaining clean equipment are practices that will consistently enhance your outcomes.

Moreover, feel encouraged to experiment with the techniques and settings provided in this guide to discover what works best for your specific projects. Each print presents an opportunity to refine your skills and achieve increasingly high-quality results with XVN-50 resin.

So, are you ready to elevate your 3D printing projects? Purchase XVN-50 resin today and apply the techniques from this guide to unlock exceptional results. Don’t forget to share your prints and experiences with us, or reach out if you have any questions. Our team is here to help ensure your success with XVN-50 resin. Visit our shop to get started and join the community of innovators transforming their ideas into reality!