Updated on March 07, 2024

Although many of us use IPA (isopropyl alcohol) for cleaning our SLA 3D printed models, not many know what impact it may have on their 3D prints. In this edition we will conduct an experiment on how IPA can affect our SLA 3D prints.

Recently, we noticed many comments online from people concerned about the dramatic shrinkage of their parts when using various 3D printing resins. This unexpected shrinkage is different from the natural shrinkage of material due to post-curing, i.e., hardening.

When SLA printed part shrinks due to ongoing curing, cracks typically occur at spots where the biggest stresses arise. For example, such spots can be sudden transitions from thick wall to thin wall like “T” joints, i.e. when thinner wall is somewhat perpendicular to the thicker one. Causes of stress-based cracks are very diverse and are definitely worth a separate blog article, therefore, we will cover this in the future.

The type of shrinkage we are interested in this experiment is completely parasitic. It is caused by IPA which we use when washing and rinsing. We have also noticed similar shrinkage when washing 3D printed objects with tap water, but level of damage was different. All in all, as IPA is a standard cleaning solution for 3D printed objects, in this article we will focus only on IPA.

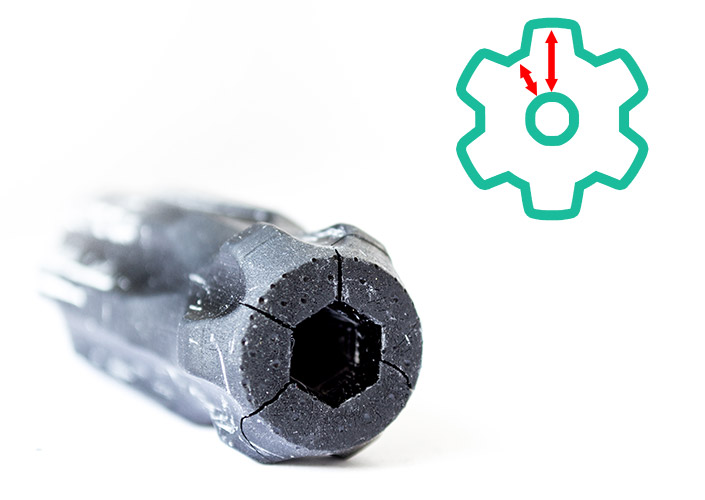

It is also interesting that this shrinkage has its specific looks. The surface typically looks chapped or even wrinkled. Cracks are deep, and even inner parts usually look damaged. Sometimes, we call it a desert-like surface. In the worst case scenario, 3D printed objects can quite easily break right in your hands without even applying serious stress.

Theoretical reasons for surface damage

Absorption

In chemistry it is well known that if you submerge something hard/solid into something liquid, it will absorb that liquid. How much will be absorbed depends on many factors, but the key point is that absorption will happen no matter what. So the longer you keep it in liquid, the more it will absorb it.

Such absorption phenomena are also inevitable in the cleaning procedure of SLA 3D prints. After 3D printing, we wash our prints in IPA. The longer we keep our models in IPA solution, the more IPA they absorb. Absorption increases because of the soft surface of fresh 3D prints, as softer materials tend to absorb surrounding liquids a lot easier.

This absorption causes SLA 3D prints to swell during cleaning. During swelling cross-linked network of polymer expands. But when you take your part out of IPA, absorbed liquid evaporates, and the polymer network tends to shrink and go back to its primary shape. Therefore, this shrinkage results in severe cracks and damage to the surface as the polymer network is not able to recover to exactly the same original structure.

It is also worth mentioning that we have executed FTIR analysis for this issue. It covered various samples that IPA has affected. All in all, our research showed that there were no obvious changes in chemistry of those samples. So we concluded that effect might be a reason of physical and not chemical alteration.

Moreover, we’ve discussed and re-confirmed that absorption of liquid may be a reason behind this surface cracking effect with professors at the faculty of chemical technology of Kaunas University of Technology.

Composition of the material

Nevertheless, it is difficult to state the exact reasons why that happens. We learned that raw materials used in resin can also cause it. Some formulas with certain raw materials are more sensitive to IPA, whereas others produce 3D printed objects that are only insignificantly affected. If you have your own version, drop us a comment below; we would be glad to discuss and learn more.

After discussing the above-mentioned facts, we decided to experiment and investigate how IPA affects various SLA 3D printing resins in different 3D printing, cleaning, and post-curing settings.

The goal of the experiment

The main goal of this experiment is to examine IPA effect on various 3D printing resins that are currently available on the market. Therefore, throughout the experiment we will try various settings of washing (with IPA), post-curing and 3D printing. Finally, after this experiment we expect to make conclusions and findings on how to reduce potential negative isopropyl alcohol impact on SLA 3D prints during cleaning.

Progress of experiment and summary of conditions

Model

First, we chose a very popular T800 Terminator EndoSkull by awesome3dgeek model for this experiment. We added attachment layer to the model and scaled it to dimensions of 25mm x 22mm x 17mm. We did not hollow it.

IPA

We used a standard IPA solution with a concentration of 99%. This is what you would typically buy at a hardware or electronics store. We did not dilute it with distilled water or other liquids. We kept IPA at room temperature.

Resins

Our team have selected 8 resins currently available on the market. We chose the black/dark versions on purpose so as to reduce chances of guessing the potential brand. We did not alter the materials. In other words, we did not add any additional pigments or other components. We purchased all 3D printing resins within 2‑3 months. Finally, we included AmeraLabs 3D resin among these materials.

DLP 3D Printer

For this experiment we decided to use DLP 3D printer, which uses Acer H6518BD projector. We 3D printed all models at 50um layer height and 50um XY resolution. Exposure time for each layer was around 2‑3 seconds. We measured the minimum time needed for a given material to cure 50um layer. Our team calculated this time separately for each material and in the same way.

Experiment steps

Our team tested each 3D resin in the following way.

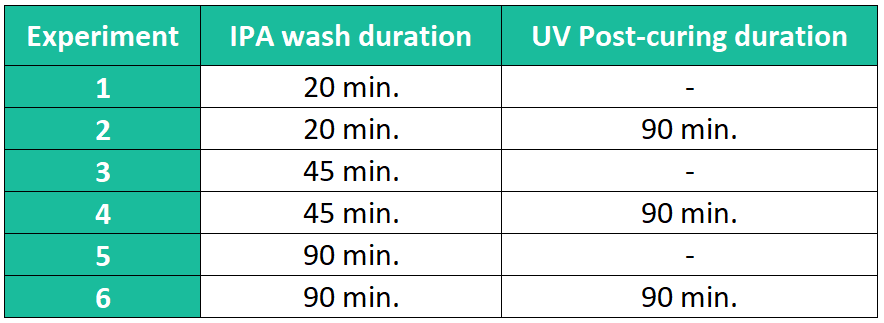

- During single 3D printing session, we printed two T-800 models at once in order to have as identical specimens as possible. Altogether, we ran three 3D printing sessions and produced six T-800 models.

- During the first session, we cleaned both T-800 models and submerged them in IPA for 20 minutes. The first model was dried, and no post-curing was done. The second model was dried and immediately post-cured for 90 minutes.

- We cleaned both T-800 models of second session and submerged them in IPA for 45 minutes. First model was dried and no post-curing was done. Second model was dried and immediately post-cured for 90 minutes.

- Models of the third session stayed in IPA for 90 minutes. We dried the first model and did no post-curing. While, we dried the second model and immediately post-cured it for 90 minutes.

All in all, the main difference among tests was how long each SLA print was submerged and cleaned in IPA and if post-curing was performed. Below is the summary of all tests.

After we completed all tests, we left all specimens at room temperature for 48 hours. After two days we investigated each specimen individually and provided you with the results below.

Results

After 48 hours we did thorough examination of the quality of each specimen and its surface. Although, there are quite a few models, we can quite easily group results and make conclusions.

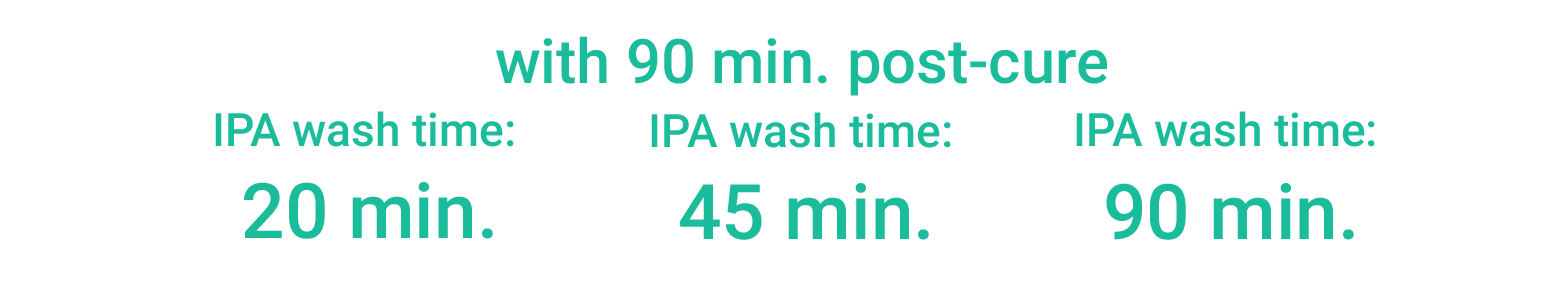

First thing to mention, the investigation of impact of post-curing was inconclusive. Some of the post-cured models showed a little bit better results than their non-post-cured counterparts. While other SLA prints developed similar surface cracks despite the fact that we post-cured them for 90 minutes immediately after cleaning with IPA. Bellow you can see several side-by-side comparisons. You can click on images to enlarge them.

Next comparison was made based on how long models stayed submerged in IPA. T-800 models of all resins that we washed and left submerged for 20 minutes showed the least overall structural and surface damage. All SLA prints that we washed and left submerged for 45 minutes showed medium overall structural and surface damage. Although some specimens were able to preserve a healthy surface after post-curing. The last group of specimens that we cleaned and left submerged for 90 minutes showed great overall structural and surface damage.

Although we have to mention, that some resins preserved quite a healthy surface even after 90 min. of cleaning with IPA.

See the images for comparison below.

Conclusions and recommendations

Examination of all specimens made it possible to make some reasonable conclusions. We think these conclusions and learnings will be useful for you and will help to minimize the potential damage of cleaning your SLA prints.

Cleaning SLA 3D prints

Major finding was that IPA (isopropyl alcohol) can and does affect the final quality of your prints. It can affect both the inner and outer parts of your 3D printed object significantly. Therefore, if you keep your printed objects submerged in IPA for prolonged periods of time, damage to your prints is usually unavoidable.

According to our results all parts that we submerged in IPA for 90 minutes and did not post-cure suffered some level of damage. Damage variation mostly depends on composition of resin. On the other hand, specimens that we submerged in IPA for 45 or 20 minutes showed lower level of visible damage.

Other factors to consider

It is also worth mentioning that these results are also greatly dependent on hardware settings. We used a DLP printer for this experiment, which uses an Acer H6518BD projector. This projector emits a lot of light that helps to effectively cure and polymerize material. Therefore, right after the printing process, objects come out in good shape and with pretty hard surfaces. Printed 3D objects with harder surfaces will absorb less IPA, and potential damage can also be reduced. The opposite can happen with LED/LCD printers, which use low-power light sources together with fast curing materials. These often produce very soft and flexible objects right after the printing process. This can result in a more severe absorbency of IPA into the 3D printed object during the washing procedure. That can obviously result in more severe shrinkage and damage to 3D-printed objects.

Moreover, this experiment applies to IPA solution only. We did not test how other washing solutions, such as ethanol or other special cleaners, can affect 3D-printed objects. Therefore, results may differ with different liquids.

Different resins – different shrinkage

Although most of our randomly selected 3D printing resins showed some degree of shrinkage and damage because of IPA, that does not mean there are no 3D resins that can avoid such shrinkage. We can shamelessly admit that the new version of our AMD-3 LED resin shows the first signs of surface damage only after sitting in IPA for several days. While we do not know the exact composition of each third-party resin, it is difficult to judge if one or another component can cause such an issue. Moreover, we do not know if all of them consist of common components as well.

Final words

This is all for today ladies and gentlemen! Don’t forget to check our shop and other blog posts:

- The Complete Resin 3D Printing Settings Guide for Beginners

- Ten reasons why you get unexpected horizontal lines on your 3D printed parts

- Impressive calibration part for resin 3D printers, together with the guide on how to understand its features

- Attachment Layer in SLA 3D printing: what you need to know

- Case Study: ViLim Ball – therapeutic device with 3D printed housing

- 6 Key Principles of 3D Printing Supports that Work

Frequently Asked Questions

Q: Can the damage caused by IPA exposure to SLA prints be reversed or repaired, and if so, what methods or treatments are available for restoration?

A: When it comes to the damage caused by IPA exposure to SLA prints, reversing or repairing it can be challenging. However, there are methods available for restoration. One common approach is post-curing the prints further to strengthen them and mitigate the effects of IPA exposure. Additionally, sanding or polishing the affected areas may help to some extent in improving the appearance and structural integrity of the prints. However, it’s important to note that these methods may not completely reverse the damage, especially if it’s extensive.

Q: Are there any specific precautions or best practices recommended for handling SLA prints during the cleaning process to reduce the risk of damage from IPA or other cleaning solutions?

A: To reduce the risk of damage during the cleaning process, there are several precautions and best practices to consider. Firstly, always handle SLA prints with care, as they can be delicate. When using IPA or other cleaning solutions, ensure proper ventilation to avoid inhaling fumes and wear appropriate personal protective equipment such as gloves and goggles. Additionally, avoid prolonged exposure of the prints to cleaning solutions, as this can exacerbate damage. Gentle agitation or brushing during cleaning can help to remove excess resin without causing undue stress on the prints.

Q: How do different environmental factors, such as temperature or humidity, influence the extent of damage caused by IPA exposure to SLA prints, and are there optimal conditions for minimizing such damage?

A: Environmental factors such as temperature and humidity can significantly influence the extent of damage caused by IPA exposure to SLA prints. Higher temperatures can accelerate the evaporation of IPA, leading to faster drying times and potentially increased damage to the prints. Similarly, high humidity levels can prolong drying times and increase the risk of residue buildup on the prints. Therefore, it’s important to work in environments with controlled temperature and humidity levels to minimize damage. Ideally, a temperature range of 20-25°C and relative humidity below 50% is recommended for handling SLA prints and cleaning them with IPA. These conditions help to ensure optimal drying times and reduce the likelihood of damage.