Introduction to Choosing the Best 3D Printer for Beginners

Welcome to the exciting world of resin 3D printing! If you’re new to resin printing technology and searching for the best 3D resin printer for beginners in 2025, you’ve come to the right place. With rapid advancements in 3D printing, choosing the right printer can be daunting. This guide simplifies the process, helping you find a beginner-friendly 3D resin printer that aligns with your needs.

In this guide, we’ll cover the top 3D resin printers for beginners, focusing on key features, ease of use, and overall value. Whether you’re starting from scratch or looking to upgrade, our insights will help you make an informed decision.

Before you start shopping, make sure to check out our Complete Resin 3D Printing Settings Guide for Beginners to learn how to fine-tune your settings for optimal print quality. Also, if you’re setting up a dedicated printing space, our Business Resin Printing Setup Guide & Checklist provides essential tips for creating an efficient and safe environment.

Embark on your 3D printing journey with confidence, knowing you have a comprehensive guide to help you select the ideal 3D resin printer. Let’s dive into the world of resin printing and find the perfect tool to kickstart your creative projects in 2025!

Disclaimer: we do not manufacture or sell 3D printers. The article overviews key features that beginners might overlook when picking their first 3D printer. We do not get any commission from any of the printer manufacturers mentioned in this article.

Chapter 1: Choosing the Right Size of Your 3D Printer

When envisioning your future print size, take into account potential larger creations and intricate projects. However, be mindful that larger printers have larger surfaces to clean, such as the build plate and resin tray, which result in increased resin wastage. Larger printers shine in printing large models or substantial quantities of smaller items.

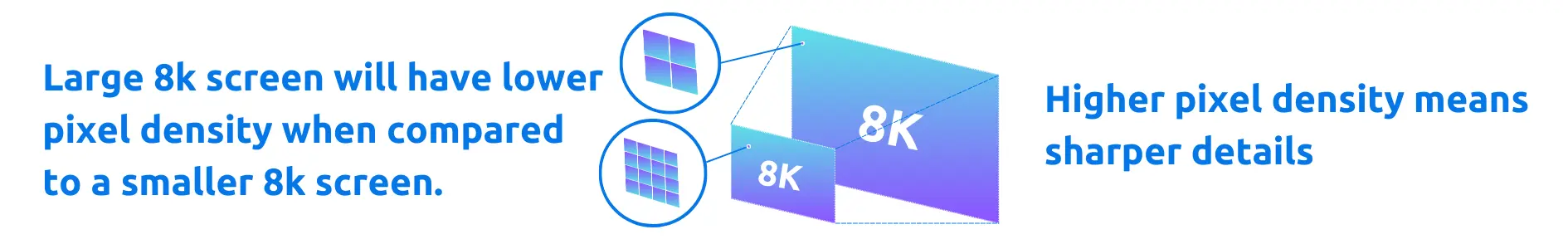

Another thing to consider is smaller printers generally boast higher pixel-density screens, producing finer intricate details (more in Chapter 4). They also prove advantageous for those who switch between different resins, offering a more practical choice.

It’s crucial to note that smaller printers often come with a more budget-friendly price tag, not only during the initial purchase but also when it comes to replacement screens, FEP film, and other consumables. In summary, consider opting for a smaller printer if your primary focus is producing small models as you embark on your 3D printing journey.

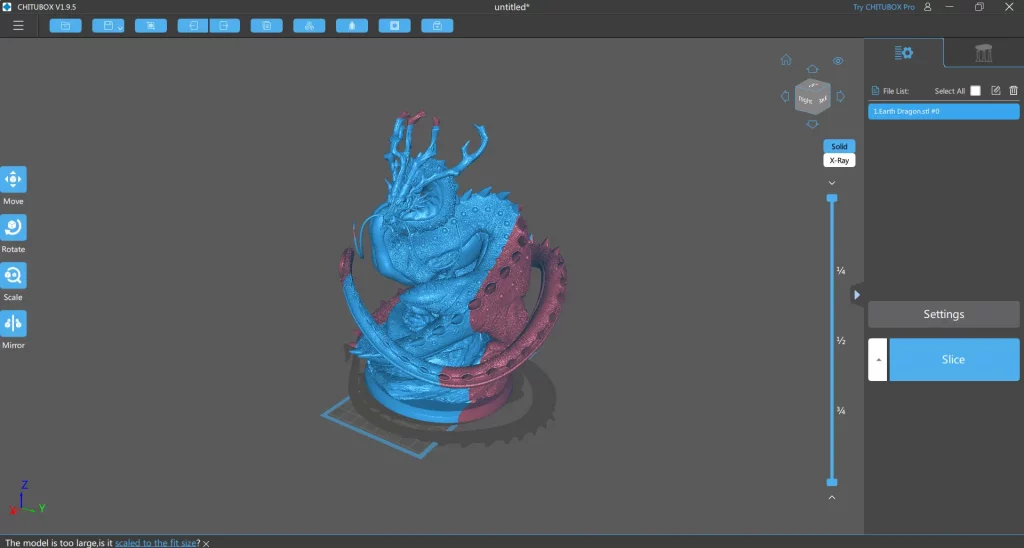

Moreover, make sure to verify that the chosen 3D printer aligns with the specific prints you have in mind. Download Lychee / Chitubox slicer software, find the printer in the printer list, and the slicer will show the illustration representing the selected printer build plate volume size. Import the file, and you will see if it fits. This step guarantees that your chosen printer can effectively handle the scope of your creative projects, ensuring optimal results and preventing any unexpected issues during the printing process.

Chapter 2: Creating Your 3D Printing Haven

For a smooth printing experience, set up a dedicated printing area, preferably situated in a dark room. This is crucial because stray light, if present, can unintentionally cure the resin in the vat, potentially impacting the quality of your prints.

It is imperative to secure your dedicated printing space, ensuring it is out of reach for both children and pets. This precautionary measure guarantees their safety and prevents accidental interference with the 3D printing process. Even if you live alone, do not place the printer in your kitchen, bathroom, bedroom, or workroom. Consider a basement, garage, warm shed, or a separate room for your resin 3D printer.

To mitigate the threat of resin fumes, ensure adequate ventilation. You can install an air vent or explore alternatives such as a laminar flow hood or specialized tents designed for effective fume containment.

Enhance your printing space with these additions: storage for resin and IPA, a nitrile glove dispenser, a paper towel dispenser, a tray for print removal, and a spot for personal protective equipment (PPE).

Gathering the supplies

Before acquiring a 3D resin printer, gather essential supplies for a seamless printing process:

- Invest in a Wash and Cure station appropriately sized for your workload.

- Shield your hands with nitrile gloves, creating a protective barrier.

- Select high-quality resin that aligns with your printing needs.

- Safeguard your eyes with UV protective glasses.

- Keep a ready supply of IPA for cleaning.

- Have a stack of paper towels for wiping and cleaning.

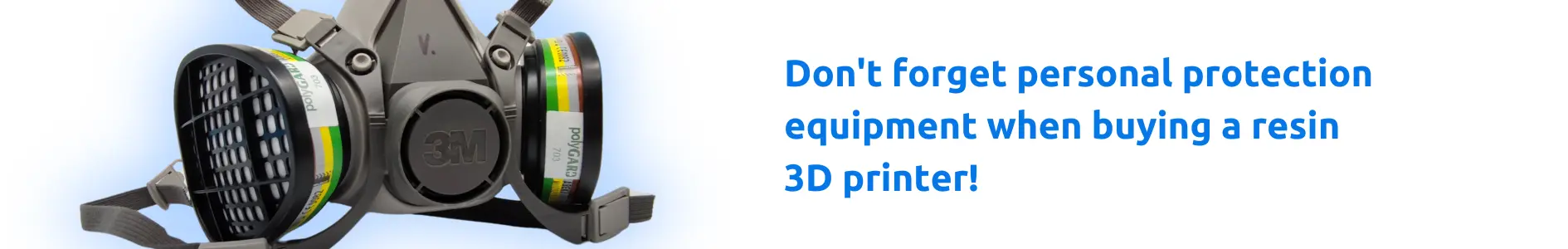

- Prioritize safety with a respirator or half mask (Organic Vapor Filter) against potential fumes.

- Get a backup USB stick, as the ones that come with 3D printers have a high failure rate.

- A silicone spatula for mixing resin in the vat.

- A metal paint scraper with a sharp edge for removing prints from the build plate with ease.

Some of the listed supplies might be included with your resin 3D printer, but always inspect their quality. Remember, while your printer choice is crucial, preparing your dedicated space beforehand sets the stage for a successful and enjoyable 3D printing journey. Envision your printing area as a safe haven for your printing endeavors.

Chapter 3: Exploring Resin 3D Printer Varieties

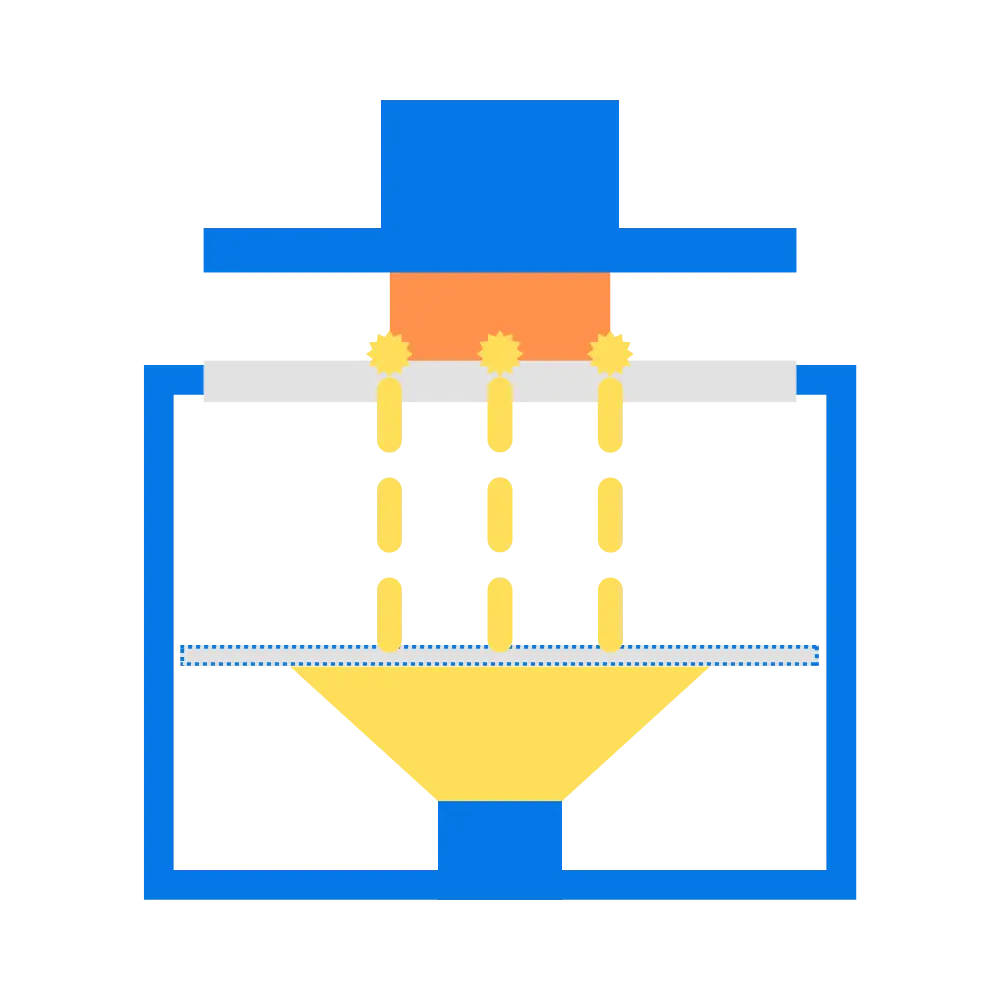

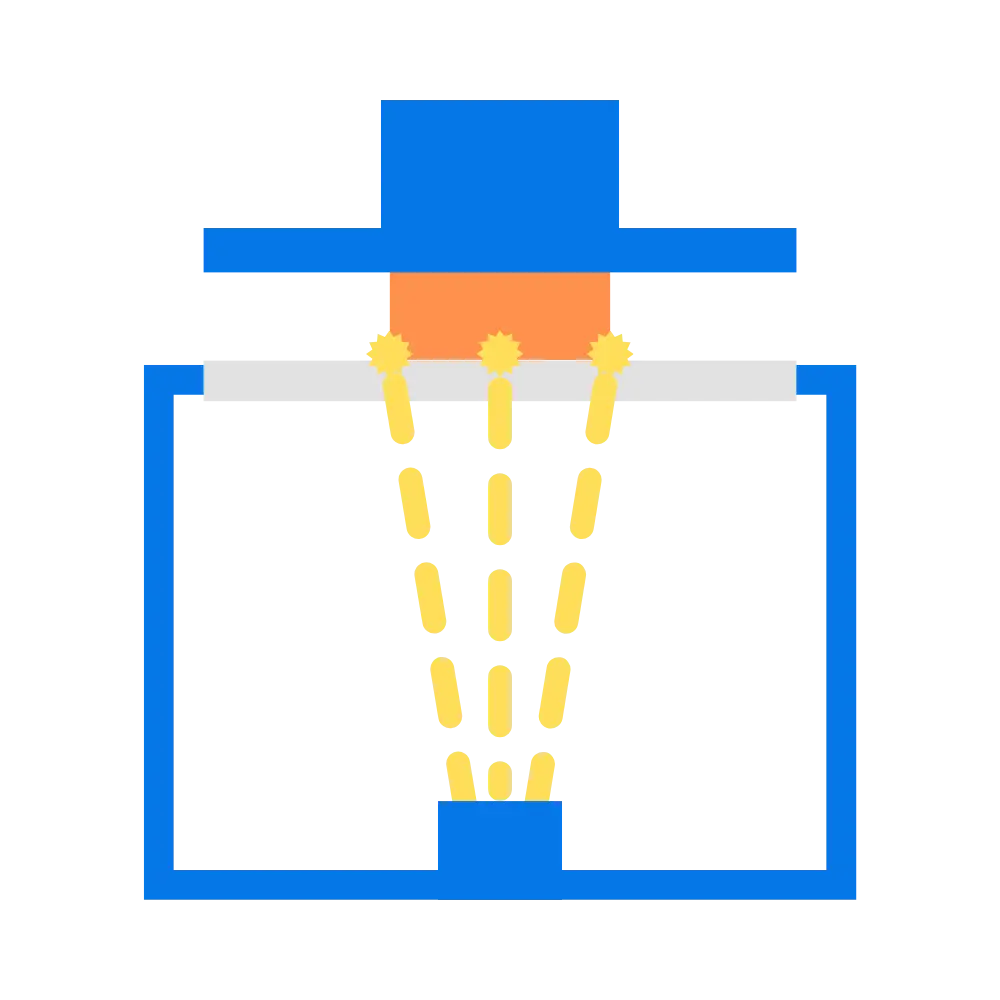

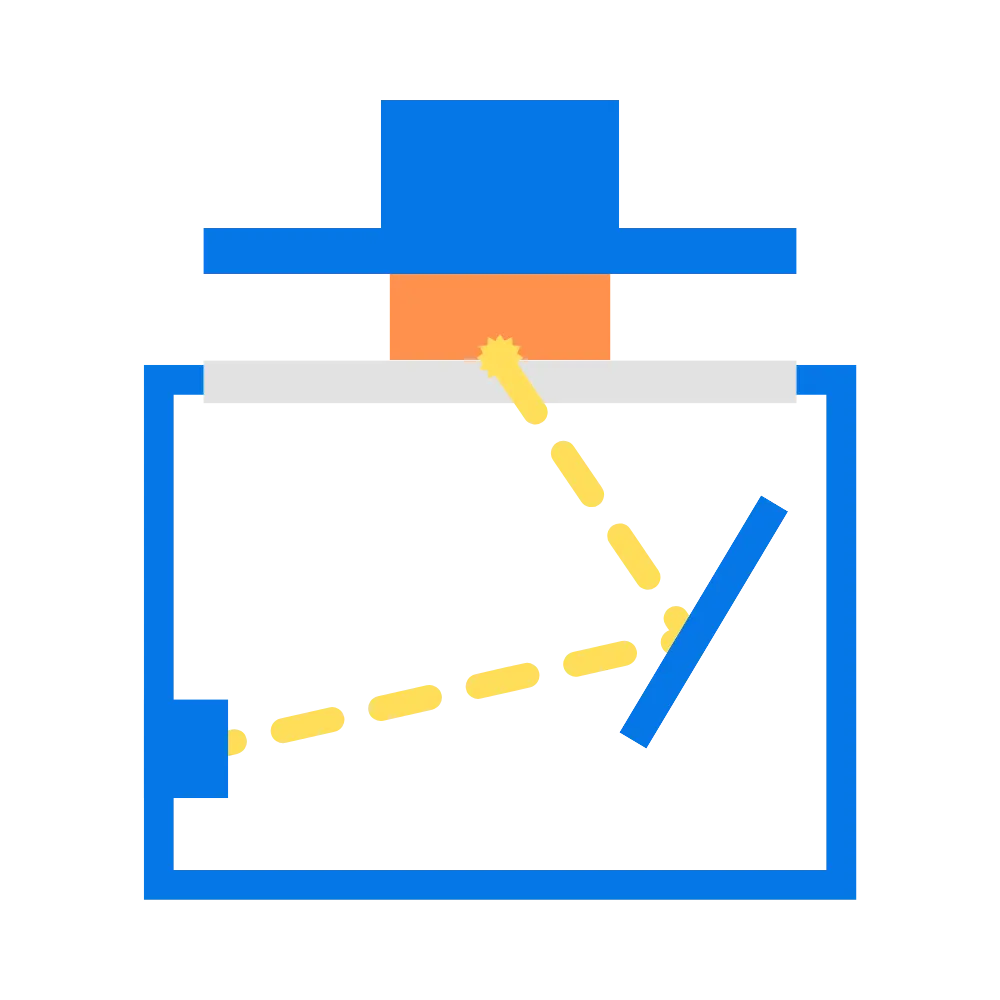

As you enter the realm of creativity, a crucial question arises: which resin 3D printer will be your trusted companion? Let’s delve into the options – LCD, DLP, and SLA printers – each presenting a unique set of features.

Types of Resin 3D Printers

| MSLA (LCD) Printers | DLP Printers | SLA Printers |

|---|---|---|

|  |  |

|  |  |

| Pros: Cost-effective Faster than SLA Beginner-friendly | Pros: No consumable screens Resistant to accidental spillages and damage Better light distribution | Pros: Potential for consistency Better surfaces as the voxels are formed differently |

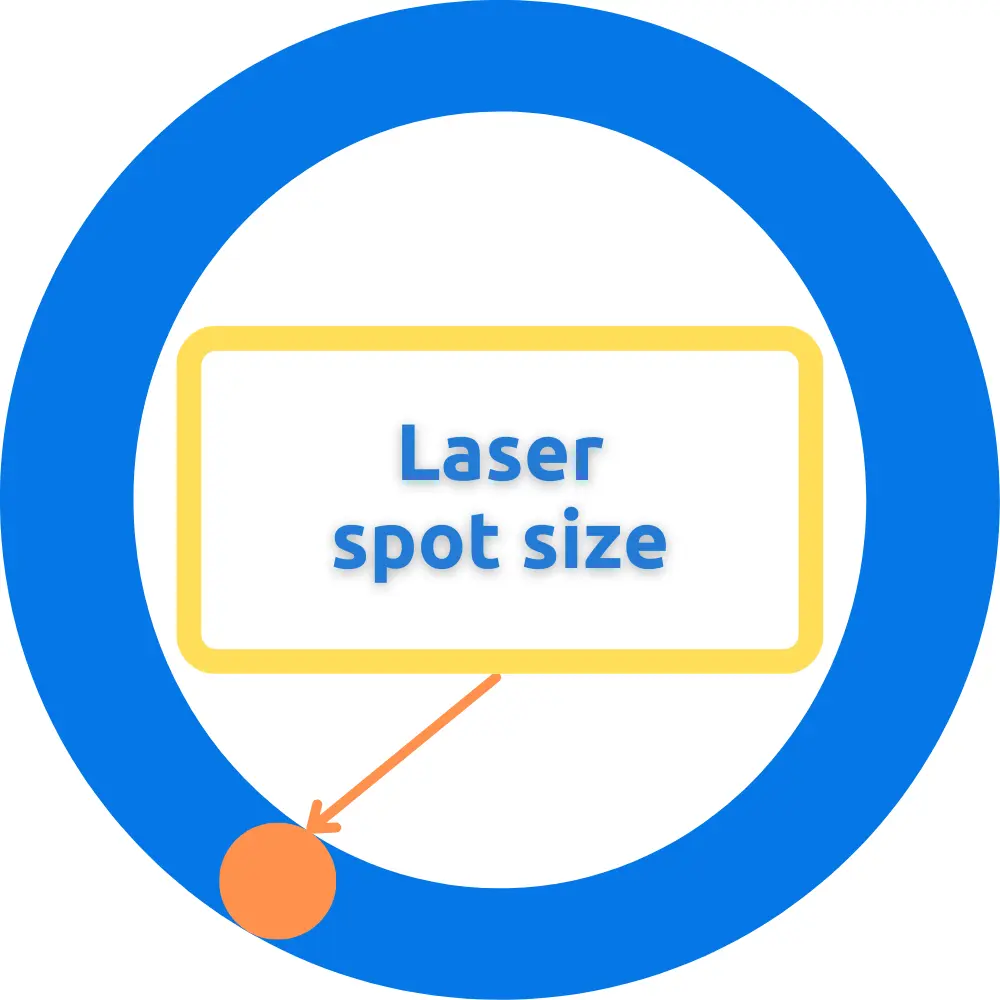

| Cons: Consumable LCD screens; Usually uneven light distribution across the screen; Low cost sometimes means lower quality and lower reliability. | Cons: Less popular, potential difficulty in obtaining spare parts; Smaller build volume; Generally more expensive. | Cons: No budget options; Slower printing speed; Lower accuracy as laser spot size is quite large. |

DLP vs. MSLA

DLP printers are key contenders in finding the best 3D printer for beginners in 2025. They stand out with no consumable screens, heightened damage resistance, superior light distribution, and a compact form. Despite their advantages, their relative obscurity might pose challenges in obtaining spare parts. Another thing to consider when contemplating a DLP 3D printer is lower build area volume. Notable DLP models like the Anycubic D2 and the Elegoo Mars 4 DLP exemplify this category.

MSLA vs. SLA

MSLA printers offer cost-effectiveness and faster print speeds, making them ideal for beginners. However, they often rely on consumable LCD screens and may exhibit uneven light distribution, potentially impacting print quality. On the other hand, SLA printers promise exceptional consistency and superior surface quality due to precise laser control. Yet, they come at a higher cost and slower print speeds, with potential accuracy limitations.

In summary, aligning with the best 3D printer for beginners in 2025 involves choosing LCD printers for cost-effective and beginner-friendly entry. DLP printers, on the other hand, eliminate consumable screens, prioritizing durability. Meanwhile, SLA printers cater to professional users despite their higher cost and slower printing speed. Overall, each resin 3D printer type has advantages and disadvantages; generally, all decent printers will provide good results.

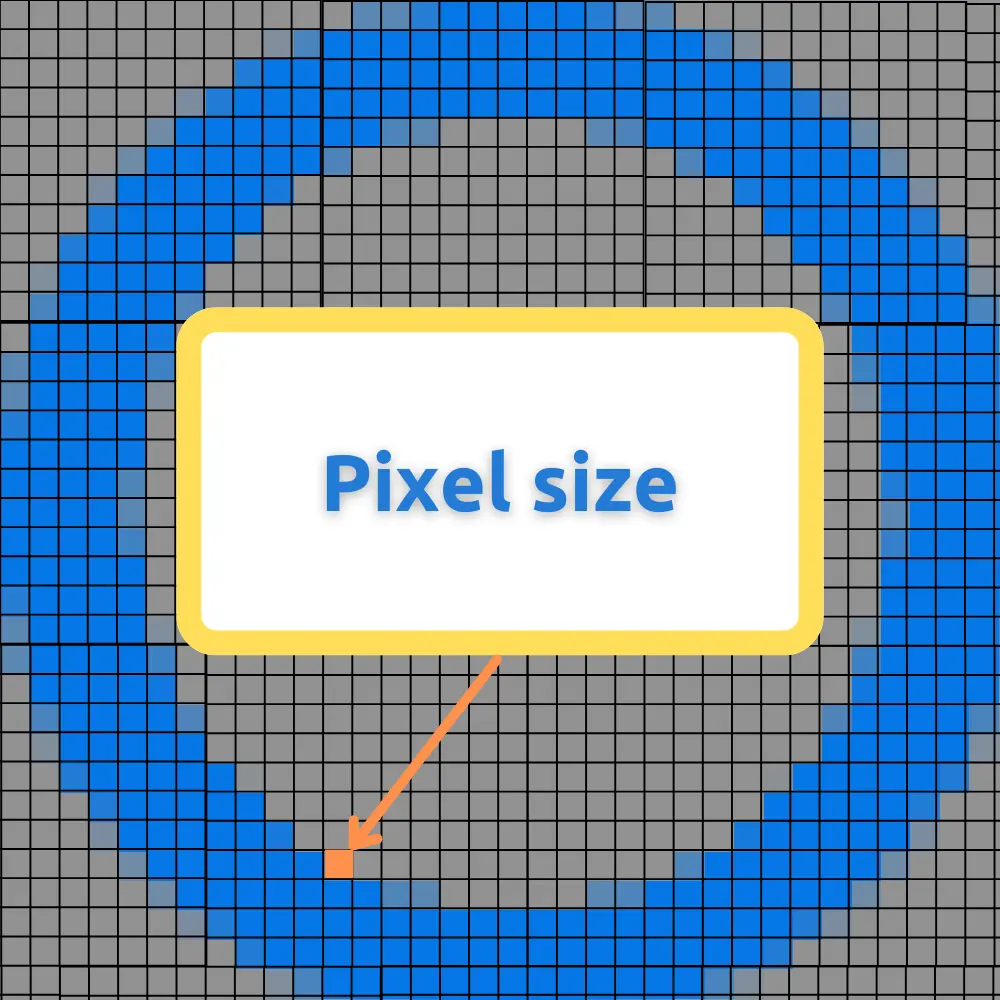

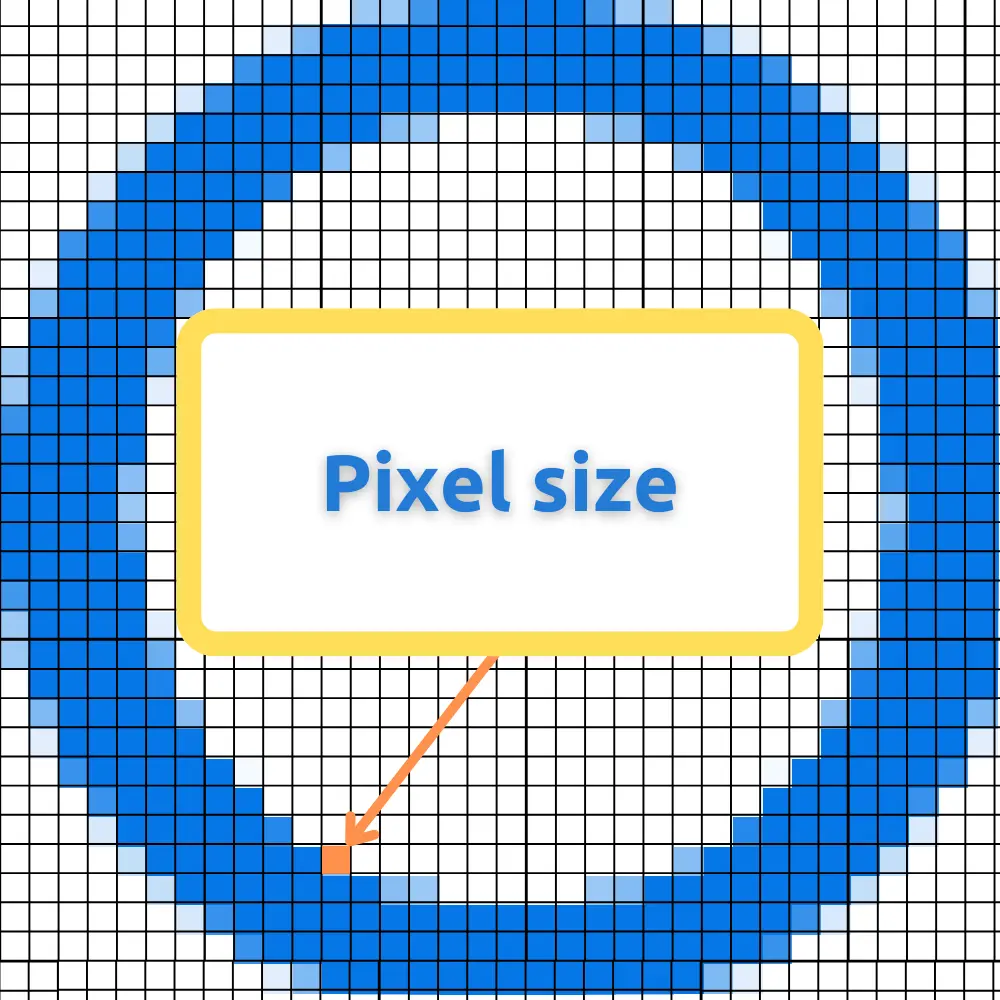

Chapter 4: Decoding Printer Resolutions

When looking into the specifications of resin 3D printers, resolution often takes precedence, yet relying solely on numerical values provides only a partial comprehension. Let us delve into the complexities to unveil the complete perspective. As highlighted in the preceding chapter, MSLA and DLP printers are characterized by resolution, while SLA printers gauge laser spot size.

Navigating through the resolution spectrum, from 2k to 24k, each increment introduces more pixels. Nevertheless, higher resolution does not invariably ensure superior prints, as additional factors come into play. Certain manufacturers, for instance, may exaggerate their printer parameters, such as advertising 7500×3240 (over 24M) pixels as 8K rather than the standard 7680 × 4320 (over 33M) pixels.

Instead of fixating on resolutions, redirect your focus to pixel size.

When looking for the best 3D printer for beginners in 2025, avoid succumbing to the allure of glossy resolution labels. Concentrate on pixel size (also known as XY resolution). Generally, smaller pixel size signifies finer details. However, this information may not always be explicitly stated in spec sheets and might not be entirely accurate. Grasping the science behind XY resolution is imperative for a precise evaluation. For instance, larger screens may have larger pixels and lower pixel density compared to smaller screens with the same resolution.

Comparing an 8-inch 8K printer to its 10-inch counterpart unveils disparities in pixel size, shape, and count. Smaller 8K printers excel at intricate details due to their smaller and denser pixels. Thus, when comparing 3D printers, look at the pixel size instead of the resolution to evaluate the details of your future prints.

It is important to note that not all pixels are uniform squares; they can vary in shape. Some printers adopt pixel configurations like 14 x 24, utilizing non-square pixels, thus impacting the visual outcome of your prints.

Z-axis & Layer Height

Another important factor that will impact the visual outcome of your prints is Layer Height. However, all printers provide similar Z-axis accuracy, capable of printing within the 10-200 micrometer layer height range. Most applications require 30-100 micrometer layers, making any printer suitable in terms of Z-axis accuracy. Nevertheless, build quality is crucial, as the Z-axis should not be wobbly.

For beginner resin 3D printer users, achieving the right balance in pixel count, pixel size, and print size ensures optimal results tailored to specific printing needs. Given that not every printer’s published resolution is accurate, conduct thorough research before selecting the ideal 3D printer for your upcoming projects.

Chapter 5: Unveiling Essential Technical Considerations for Your Resin 3D Printer

Embarking on the quest for the perfect resin 3D printer for beginners in 2025 demands an examination of technical features. Beyond the fundamental considerations of type and resolution, immerse yourself in the nuanced characteristics that elevate a printer from a mere tool to a reliable companion for your creative ventures.

Key Technical Specifications to Look Into

When considering 3D printers, prioritizing build quality and design decisions is crucial. The printer’s sturdiness, ease of cleaning and maintenance are paramount. Avoid printers with intricate nooks and crannies, as cleaning resin spillages can be challenging, especially if the resin gets cured within those spaces. Additionally, selecting orange, yellow, or red printer lids is recommended to repel UV light interference, which could compromise print quality. Conversely, blue covers may lack adequate UV light blockage. Opting for lids with hinges facilitates ease of use, eliminating the need for extra space while working with the printer.

When evaluating the LCD screen, focus on its specifications. Prioritize monochrome screens over old-generation color RGB ones, as they tend to be slower and deteriorate quickly. Light uniformity should ideally be above 80%; consulting independent reviews on this aspect is advisable. Light source power, measured in mW/cm2, dictates resin curing speed and should be considered carefully.

Build Plates & 3rd Party Resins

Build plate leveling is essential for stability. A Standard 4-screw leveling system is preferable over self-leveling mechanisms, particularly in budget models, due to potential troubleshooting difficulties. Regarding the VAT tray, opt for models with replaceable FEP sheets to minimize wasteful replacements. Consider the film material – FEP or NFEP for smaller printers and ACF for larger ones. A double metal frame on the VAT tray facilitates easier FEP replacement.

An openness to third-party resins expands possibilities, providing a limitless array of materials for printing. Select specifications that align with your specific needs, considering your future resin 3D printing projects to ensure essential features are in place. Evaluate which printer best aligns with your priorities and creative visions, as not all resin printers are created equal.

Nice to Have Features

In addition to the primary specifications, several features contribute to enhancing the overall printing experience:

- Auto Recovery After Power Loss ensures convenience by salvaging significant prints, allowing the printer to resume operation after a power outage, thus saving both resin and time.

- The Resin Heater is another feature that improves print consistency, though be wary of direct airflow into the resin. Optimal setups involve heaters blowing air within the cover or VATs equipped with heat bands to prevent inconsistent airflow, which can disrupt the printing process and cause undesirable effects such as layer lines or random failures.

- Wi-Fi/LAN Connectivity offers practicality, although remote printing is often rare due to the need to ensure resin levels, proper mixing, etc. However, the elimination of USB sticks adds convenience, provided a stable connection is maintained, and dedicated apps are utilized.

- Resin Auto-filling proves beneficial for extensive or large-scale printing. Check the compatibility with different resin types and ensure a straightforward cleaning process for resin switching.

- A Deeper Resin Tray facilitates the printing of larger models without the need for resin replenishment during the process.

- Resin Tray With Small Feet Underneath prevents FEP damage when placing the tray on a table.

- Resin Volume Indicators on the Tray offer convenience by aiding in monitoring resin levels, thus preventing unexpected interruptions during critical printing processes.

While these features undeniably enhance the overall printing experience and cater to the needs of beginners in 2025, their suitability ultimately depends on individual preferences.

Not All That Glitters is Gold

In the quest for the best 3D printer for beginners in 2025, you’ll come across features that may sound enticing but often lack practical utility. Let’s unravel some commonly overhyped features and gimmicks that might not contribute as much as advertised.

Features to Approach with Caution

- Printing Speed Metrics (mm/hour) – not a reliable metric for comparison between printers. The actual speed depends on many factors, such as lift speeds, wait times, etc. Most speed settings are print-dependent and can be fine-tuned in slicer software. Do not be swayed solely by this number in the specifications.

- Carbon Filters – initially touted as effective, they lose their effectiveness rapidly, rendering them useless after a couple of prints. Additionally, the absence of a noticeable smell does not guarantee the absence of odorless, potentially harmful chemicals in the air. Rely on proper ventilation and safety measures instead.

- Print Monitoring Cameras – seem appealing but often fall short in practicality. With printers covered by hoods in a dark environment, the effectiveness of monitoring cameras is severely limited. Keeping the printer in the dark minimizes the risk of stray light interference. Cameras struggle in low-light conditions, and adding an additional light source would defeat the purpose of the printer cover.

- Perforated Build Plates – Marketed for better adhesion, they come with downsides – they tend to waste more resin (seeping into the holes) and are challenging to clean. These build plates make sense only on large printers.

- Flex Build Plates – seem convenient, but can introduce issues like layer shift. Cleaning can also be problematic. Beginners should be aware of potential complications.

Navigating beyond the shiny features and focusing on practical aspects that genuinely enhance your printing experience is essential. Ensure that your choice aligns with your needs and avoids falling prey to gimmicks.

Conclusion: Finding the Best 3D Printer for Beginners

Choosing your first resin 3D printer requires careful planning for a smooth start. Take note of these important tips as you make your decision:

Resist Early Adoption Temptations: New printer models may harbor unresolved issues requiring future patches and might lack full support in free slicer software versions.

Exercise Caution with Pre-Orders: They often come with delays and unforeseen issues. Opt for established and reviewed models.

Beware of Crowdfunding Platforms: Be cautious when considering printers from crowdfunding platforms, particularly Kickstarter. The 3D printing landscape has seen scams – avoid unverified projects.

Rely on Honest Reviews: Trustworthy and unbiased YouTubers like Fauxhammer, VogMan, Slice Print Roleplay, and others offer honest 3D printer reviews, highlighting both strengths and weaknesses.

Engage with the Community: Participation in user groups dedicated to specific printer models provides practical insights, troubleshooting tips, and shared experiences.

Consider tapping into local 3D printing communities or friends offering printing services for a small fee. This cost-effective approach saves money and eliminates the need for dedicated printing space.

Patience and diligent research emerge as your strongest allies. Keep in mind the knowledge within the 3D printing community; seek guidance from forums and user groups. Yet, always trust your own judgment; not everything you encounter online is reliable.

Don’t forget to check out our Beginner’s Guide to 3D Printing Settings and AmeraLabs Town Calibration Part for a smooth start!

May your journey into 3D printing be filled with precision, creativity, and boundless exploration. Happy printing!

Frequently Asked Questions

Q: How does the environmental impact of resin printing, including factors such as resin waste and energy consumption, differ between various types of resin printers available to beginners in 2025?

A: The environmental impact of resin printing varies based on factors such as the type of printer and its usage. Generally, resin printing tends to generate more waste than other 3D printing methods due to support structures and excess resin. However, advancements in technology have improved efficiency and reduced waste. Beginners in 2025 can mitigate environmental impact by selecting printers with efficient resin usage and minimal support material generation. Some printers may offer recycling or responsible disposal options for used resin. Additionally, considering energy consumption is important, as larger printers or those with extra features may require more power.

Q: Are there any emerging regulations or standards in the 3D printing industry, particularly concerning resin printing, that beginners should be aware of when selecting a printer?

A: Although there are no specific regulations solely for resin printing, beginners should consider broader regulations and standards applicable to 3D printing overall. These encompass safety standards for handling resins and operating machinery, regulations regarding emissions or waste disposal, and product safety standards for printed objects, particularly for specialized applications like medical or aerospace use. Furthermore, as the 3D printing industry progresses, ongoing developments in regulatory frameworks concerning intellectual property rights and licensing of 3D-printed designs may arise.

Q: Can insights be provided into the long-term costs associated with maintaining and operating a resin printer for beginners, considering factors such as resin refills, replacement parts, and ongoing maintenance requirements?

A: Understanding the long-term costs of owning a resin printer involves considering more than just the initial purchase price. It also includes ongoing expenses such as resin refills, replacement parts, and maintenance. Beginners should factor in additional costs like Isopropyl alcohol (ISO) for cleaning prints and equipment, which can recur. They should also consider the need for nitrile gloves and other personal protective equipment. Printers allowing third-party resins may offer more flexibility and potentially lower operating costs. Maintenance costs can vary depending on the printer’s design and complexity. Factors such as the lifespan of consumable parts (like FEP films or LCD screens) and the availability of replacement components affect overall expenses. Beginners should consider these factors when budgeting for their resin printing endeavors to ensure they’re prepared for both initial investment and ongoing costs.